Bently Nevada, Baker Hughes

Summer ‘24

Field Engineering Internship

During my 13-week internship at Baker Hughes in Minden, NV, I worked in the Field Services division under the guidance of Raymond McTier (Customer Service Manager).

This hands-on experience involved training, field service support, and technical analysis focused on rotating machinery and condition monitoring solutions.

This internship strengthened my technical expertise in vibration analysis, predictive maintenance, and industrial automation. Working alongside industry professionals, I gained insight into real-world equipment diagnostics and the strategic implementation of asset management solutions.

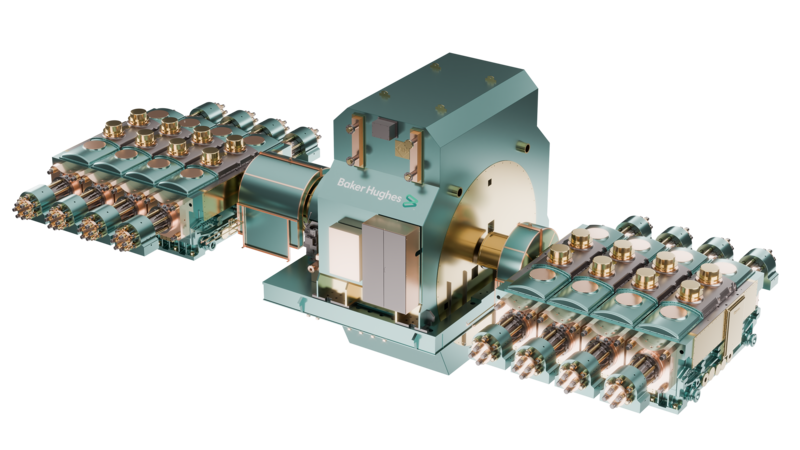

Cordant MachineEdge

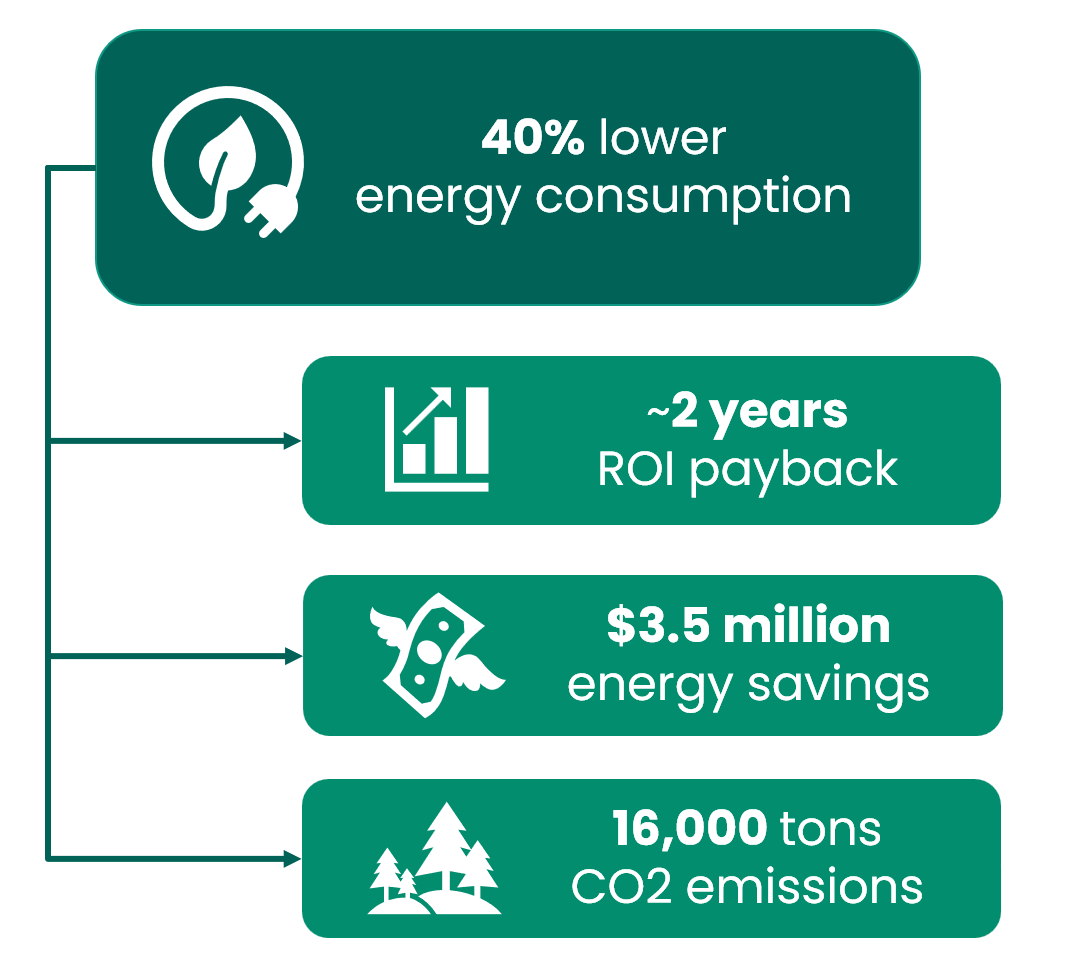

Industrial pump systems often operate inefficiently, leading to high

energy consumption and maintenance costs. Baker Hughes' Cordant MachineEdge integrates AI-driven optimization to address this issue.

I evaluated MachineEdge’s impact on energy efficiency and predictive maintenance for rotating equipment by analyzing sensor data integration, AI-based intelligence, and motor speed optimization to assess the system’s effectiveness and studied real-world energy savings and ROI potential.

I identified a 40% reduction in energy consumption, a 2-year ROI payback, and potential savings of $3.5 million with 16,000 tons of CO₂ reduction, demonstrating the feasibility of smart industrial automation.

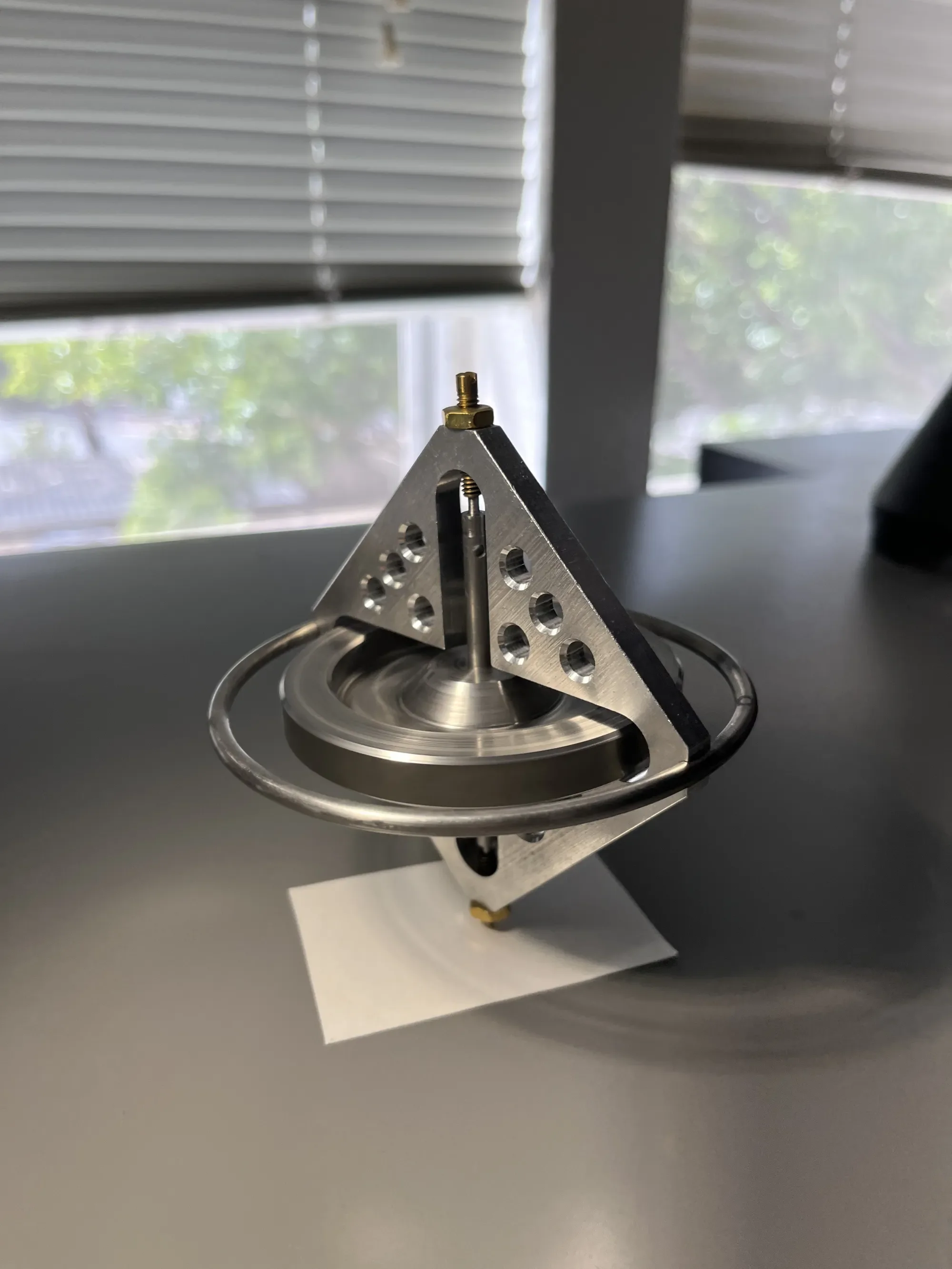

Hetch Hetchy Site Visit

The Hetch Hetchy hydroelectric system includes multiple powerhouses requiring efficiency analysis and maintenance assessments to ensure long-term operation.

I conducted an on-site evaluation of three units at Kirkwood Powerhouse and two units at Cherry Powerhouse to assess their power generation capabilities by examining turbine vibration data, mechanical integrity, and power output metrics as well as evaluated potential upgrades for preventive maintenance strategies.

I was able to provide insights for power optimization, identifying areas for efficiency improvements ahead of the March 2025 project timeline.

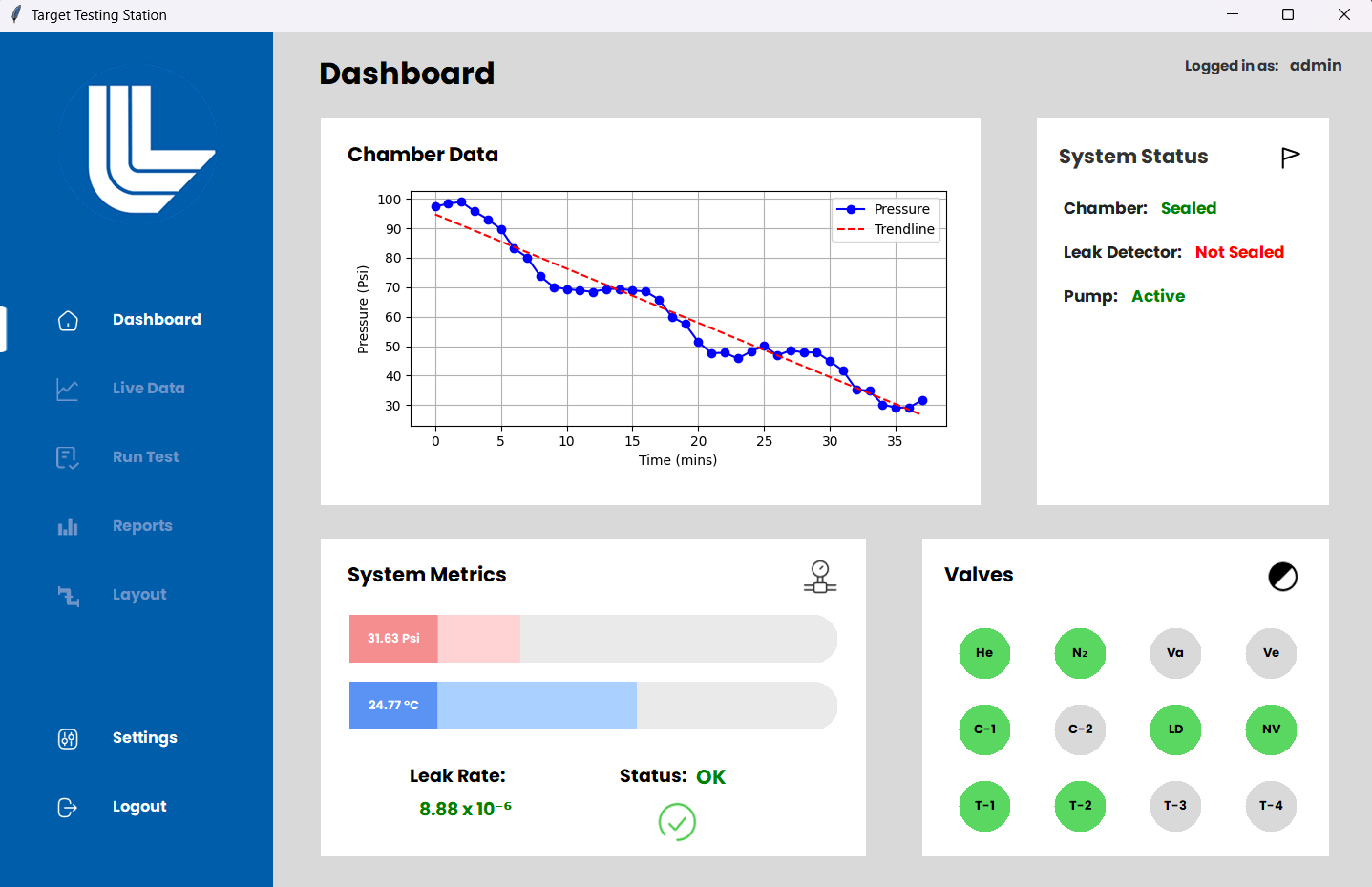

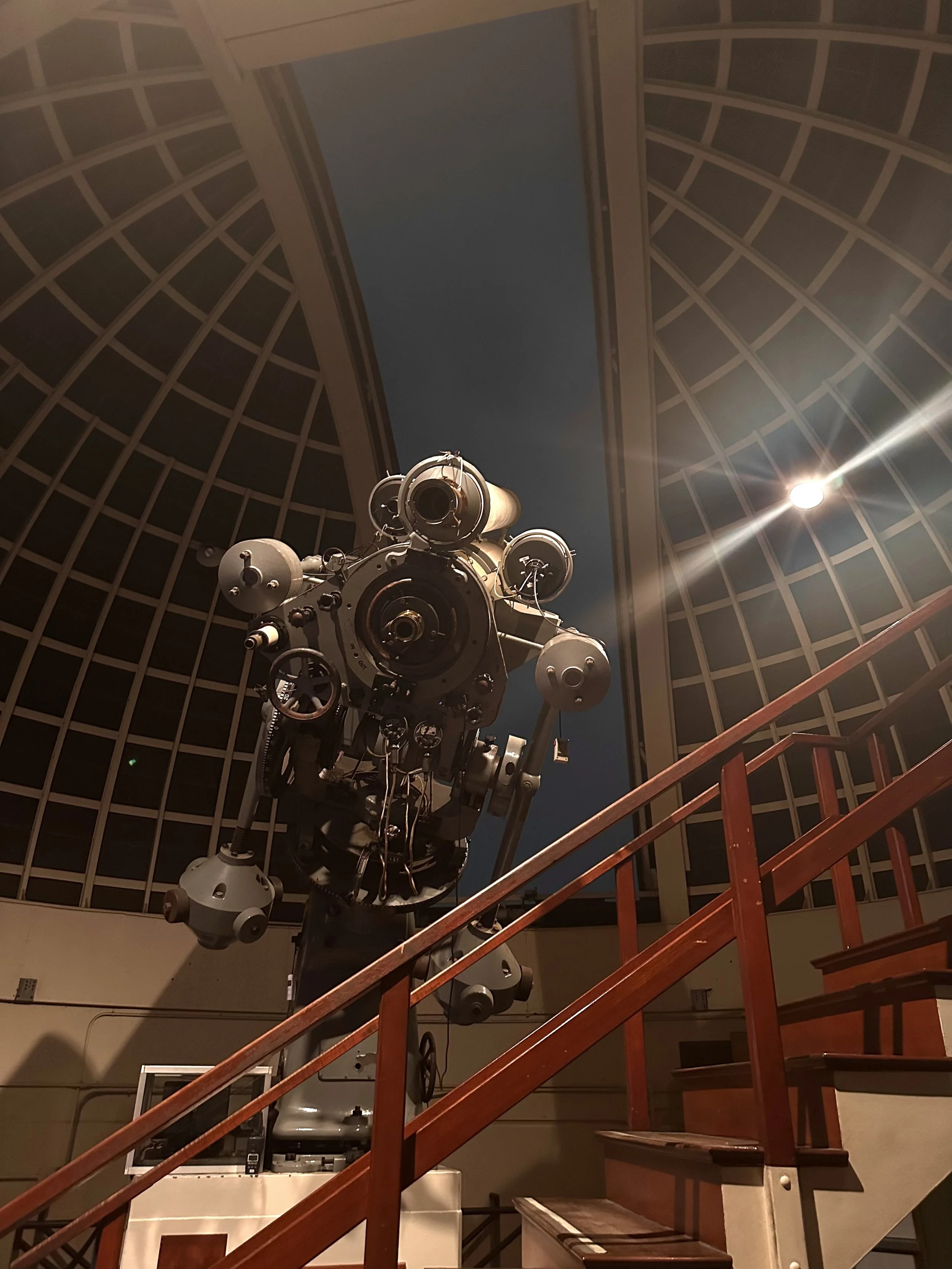

Remote Monitoring & Diagnostics Center

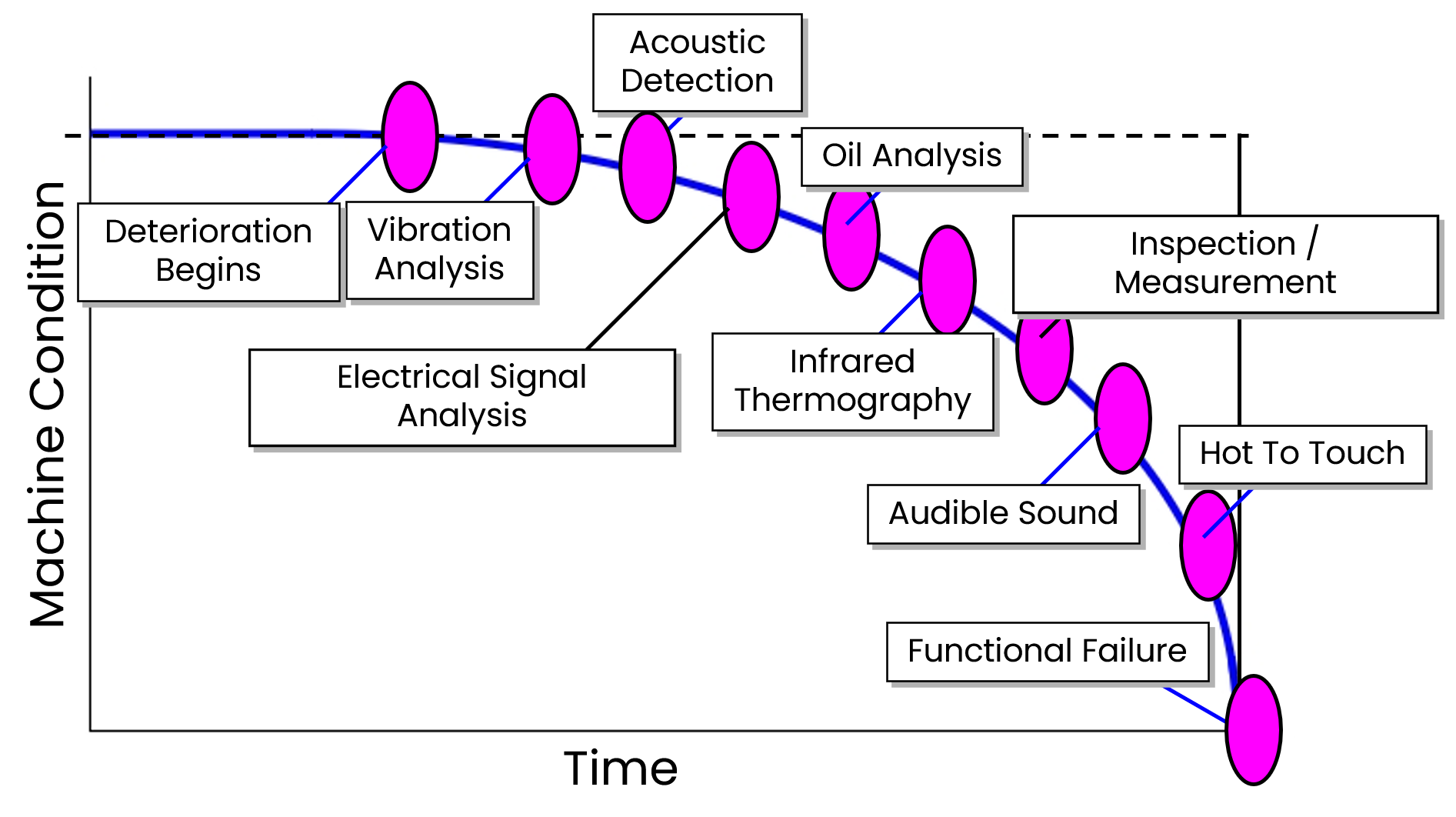

The RM&D Center is responsible for real-time condition monitoring of industrial assets, enabling predictive maintenance to prevent failures.

I was able to gain firsthand experience in diagnosing rotating machinery issues through vibration data analysis and failure trend identification. I observed data processing from condition monitoring systems, analyzed vibration signals, and studied failure detection techniques for electrical, mechanical, and hydraulic components.

At the end, I developed a deeper understanding of preventive maintenance strategies, including Run-to-Failure (RTF), Condition-Based Maintenance (CBM), and Proactive-Centered Maintenance (PCM).

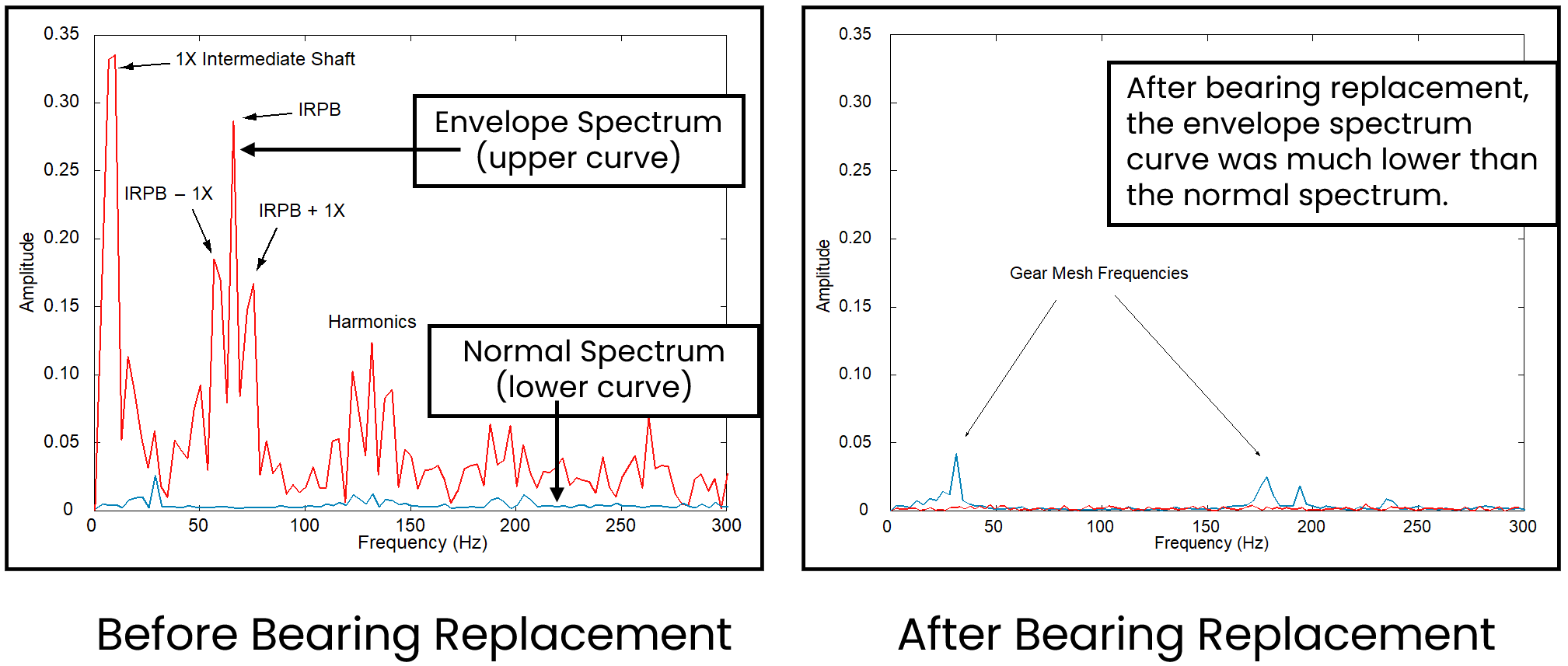

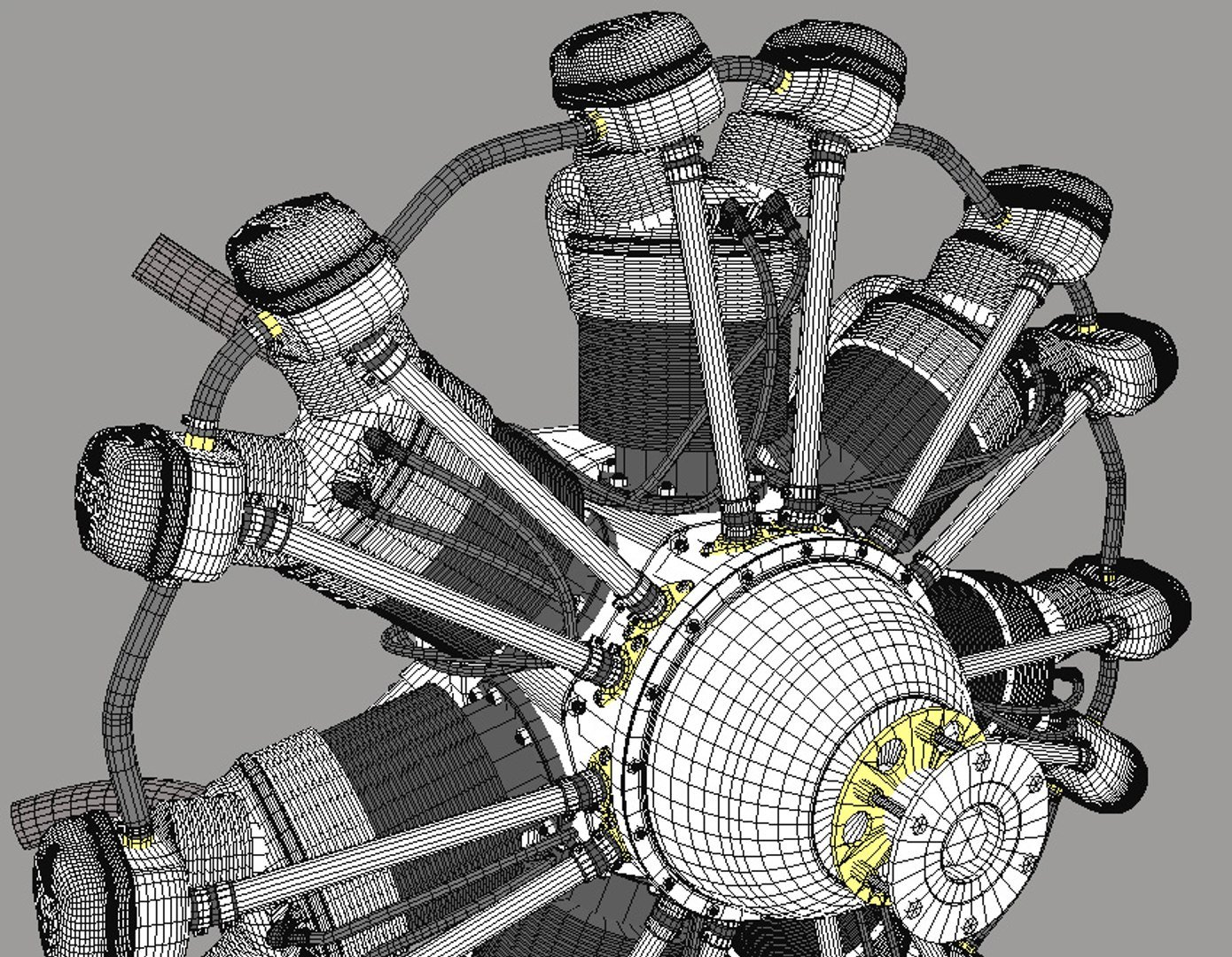

Buck’s Creek Site Visit

The Buck’s Creek hydroelectric plant required an assessment of Unit 2’s vibration issues to ensure operational stability.

By investigating vibration anomalies affecting turbine performance and recommending corrective actions, I analyzed proximity probe data, pressure imbalances, and sub synchronous shaft vibration to determine the root cause of instability.

I identified flow separation and vortex formation as contributors to vibration issues, recommending structural reinforcements and monitoring enhancements for improved reliability.

Tech Support Growth Initiative

The Bently Nevada NA West division aimed to expand technical support and strengthen customer engagement by optimizing case resolution processes.

I assisted in re-establishing the initiative by streamlining support workflows and enhancing customer outreach by filtering through technical support cases, identified common failure patterns, and reached out to potential customers for proactive engagement.

I helped refine the tech support process, improving response efficiency and customer satisfaction, ultimately contributing to Bently Nevada’s service growth initiative.