EME 50 | UC DavisGyroscope & Totem Machining

One of the coolest projects? Building a gyroscope from scratch.

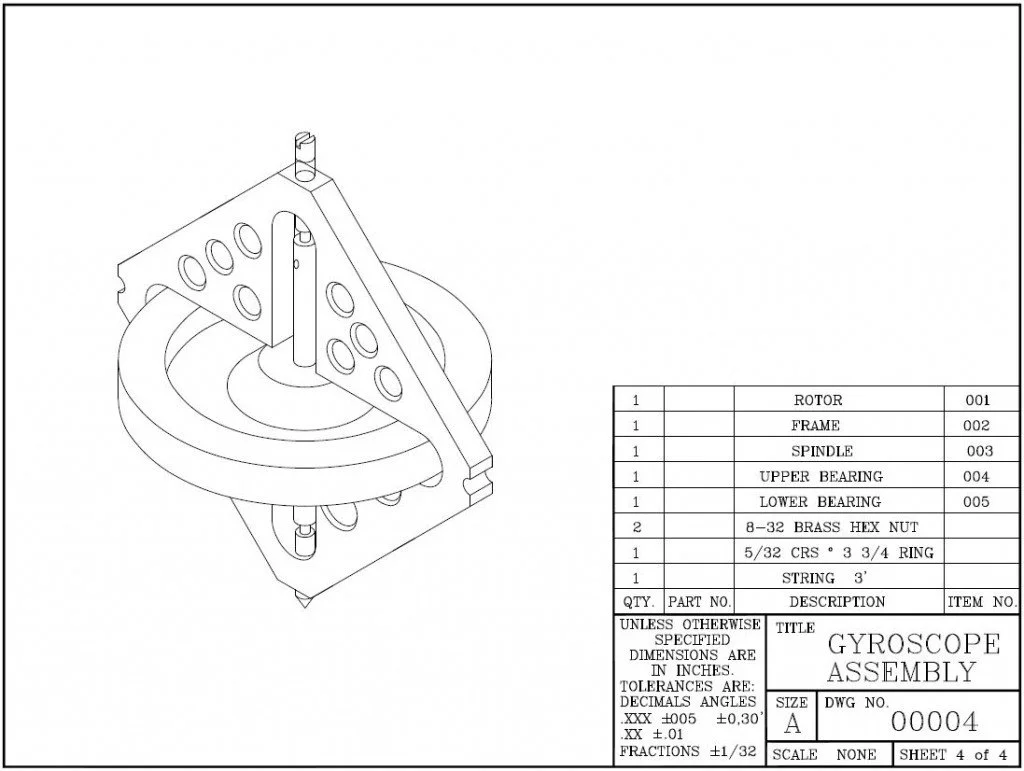

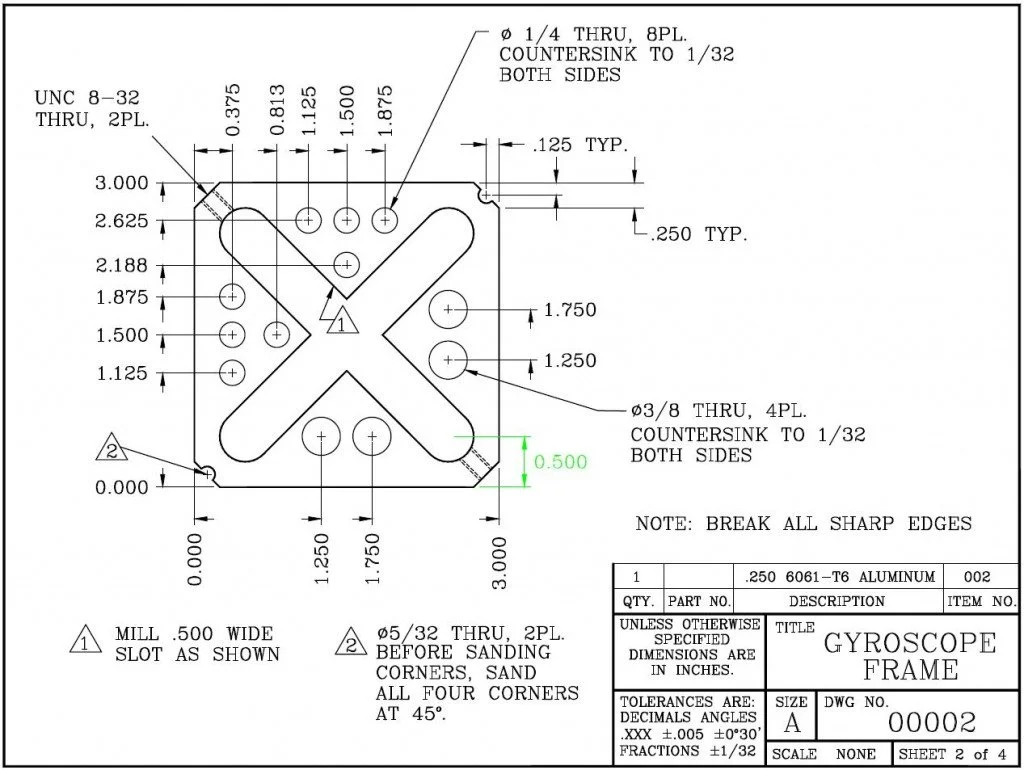

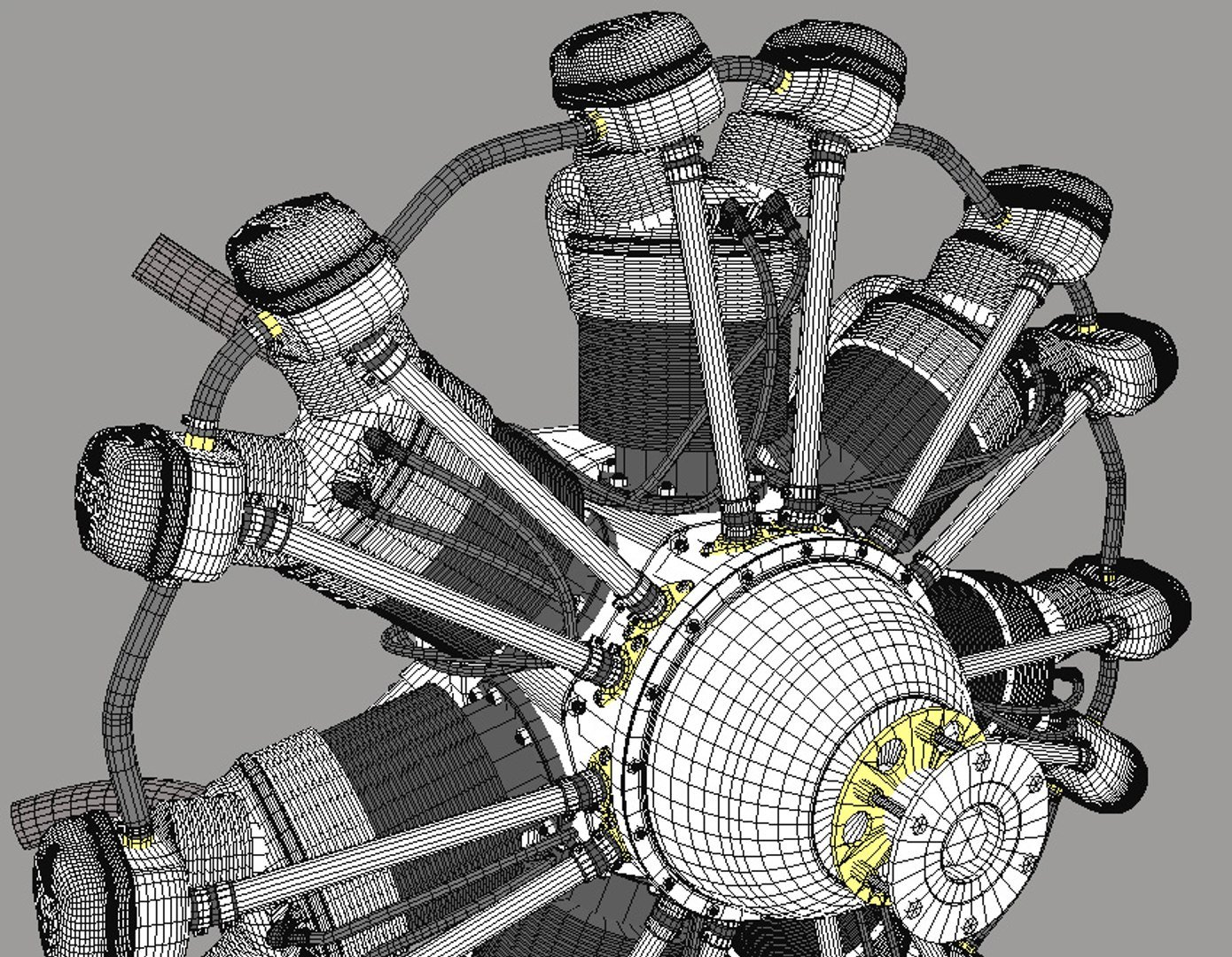

After learning about chip loads, material removal rates, and machining techniques, you take those skills to the shop and bring a working gyroscope to life.

And it’s not just about making one, it’s about making the best one. At the end of the quarter, the Gyro Spin-Off determines whose gyro spins the longest, with the winner scoring a custom plasma-cut stand.

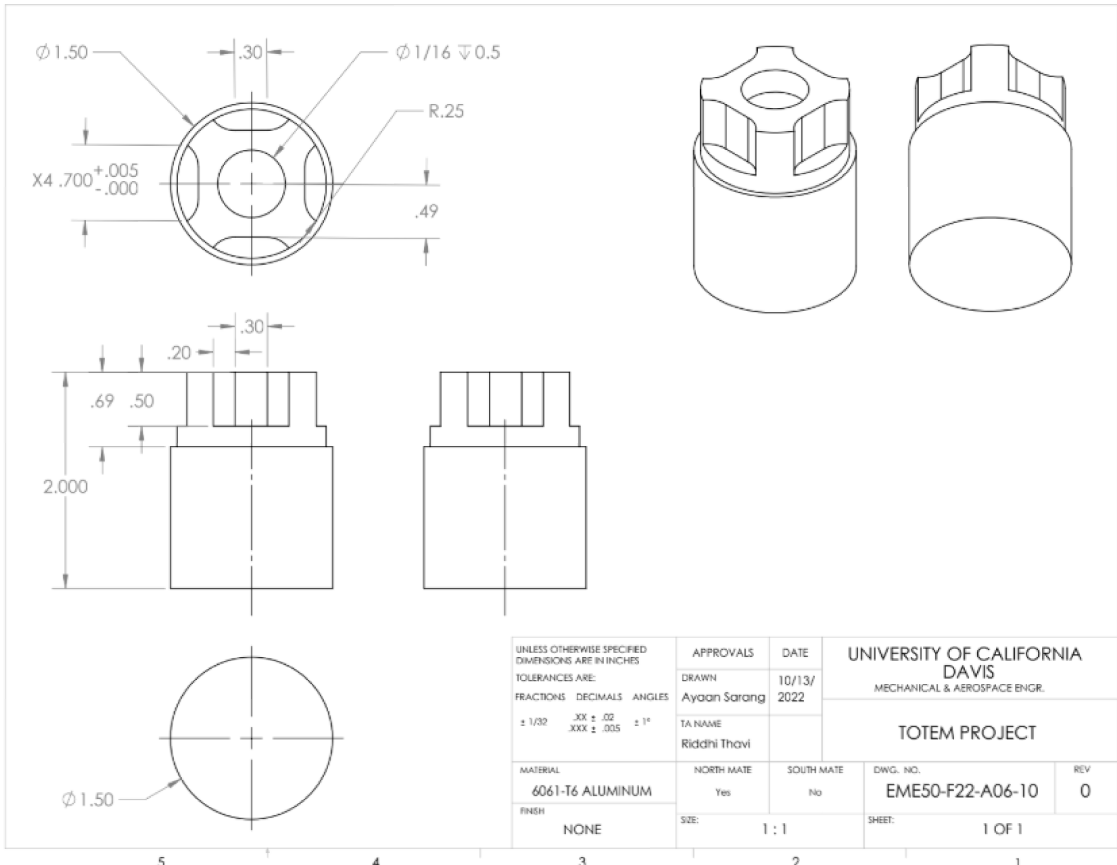

Each student designed the north or south end of a totem in SolidWorks, ensuring that both halves fit together seamlessly. At the end of the quarter, every piece was stacked to create a towering testament to design, machining, and teamwork.

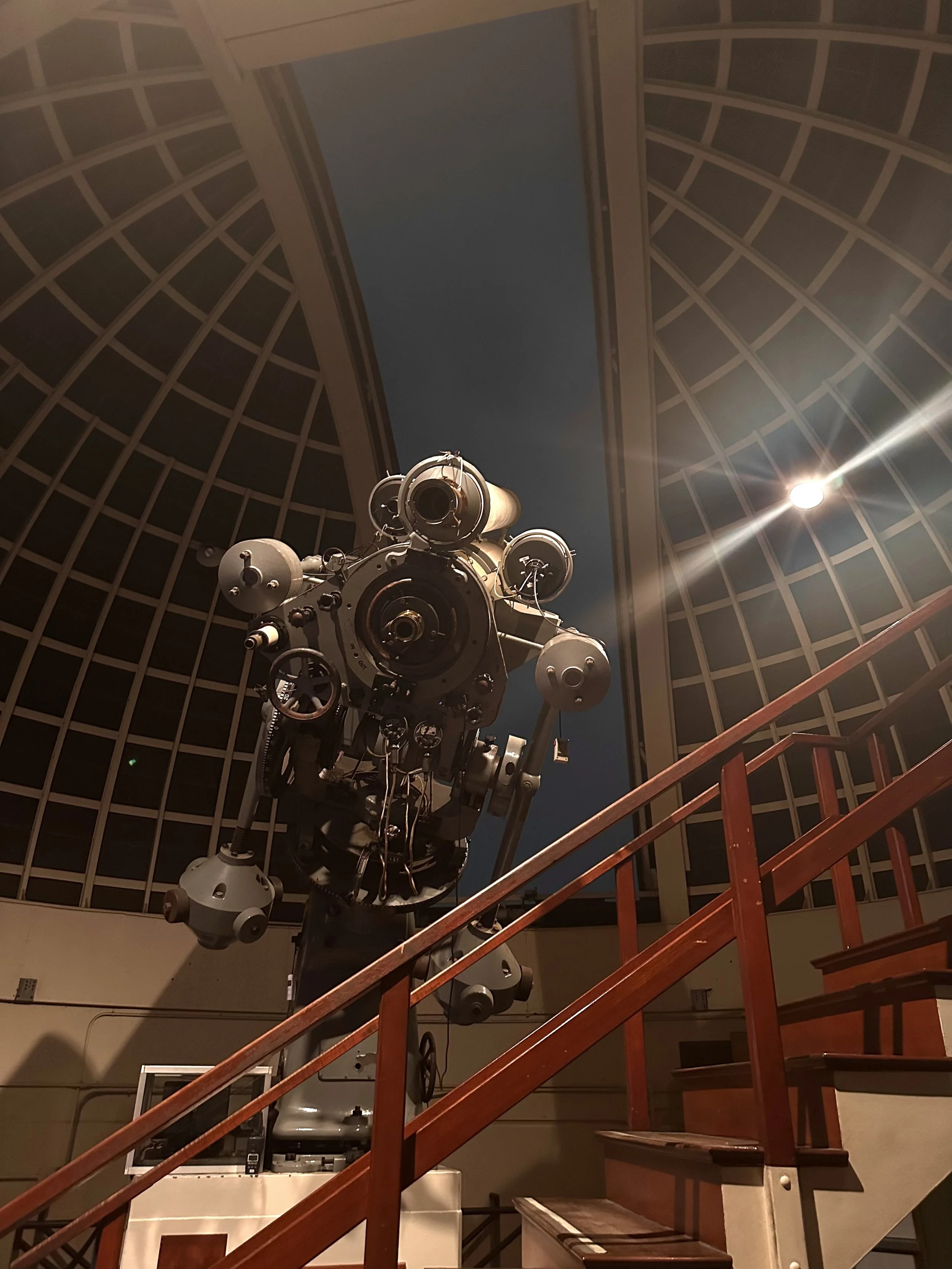

Bringing the designs to life required manual machining on the lathe, mill, and drill press, along with high-precision CNC milling on a DMU 50. The result? A hands-on lesson in manufacturing that was as fun as it was technical, because nothing says engineering success like a perfectly machined totem pole.