Baker Hughes

Summer ‘23

Mechanical Engineering Internship

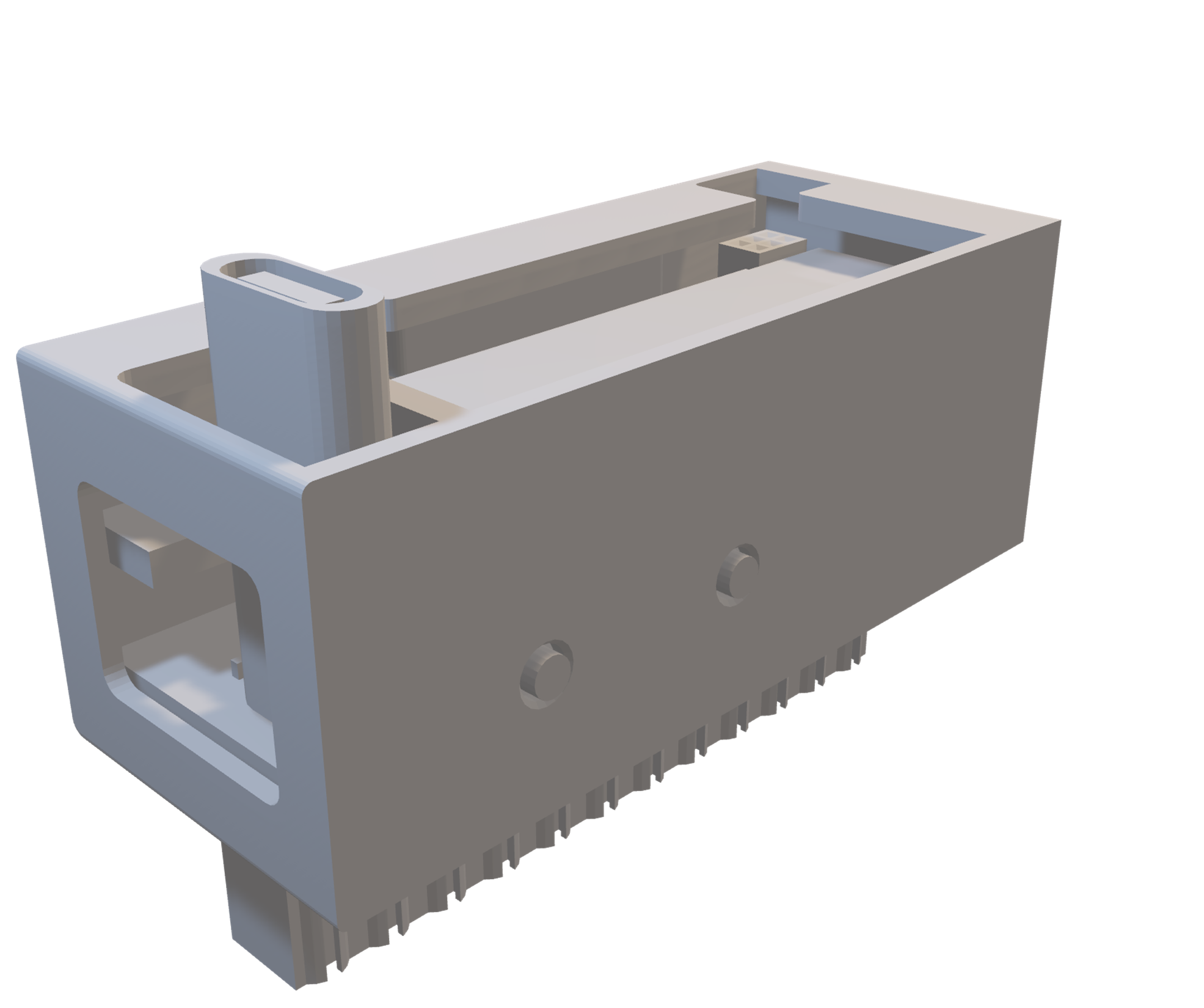

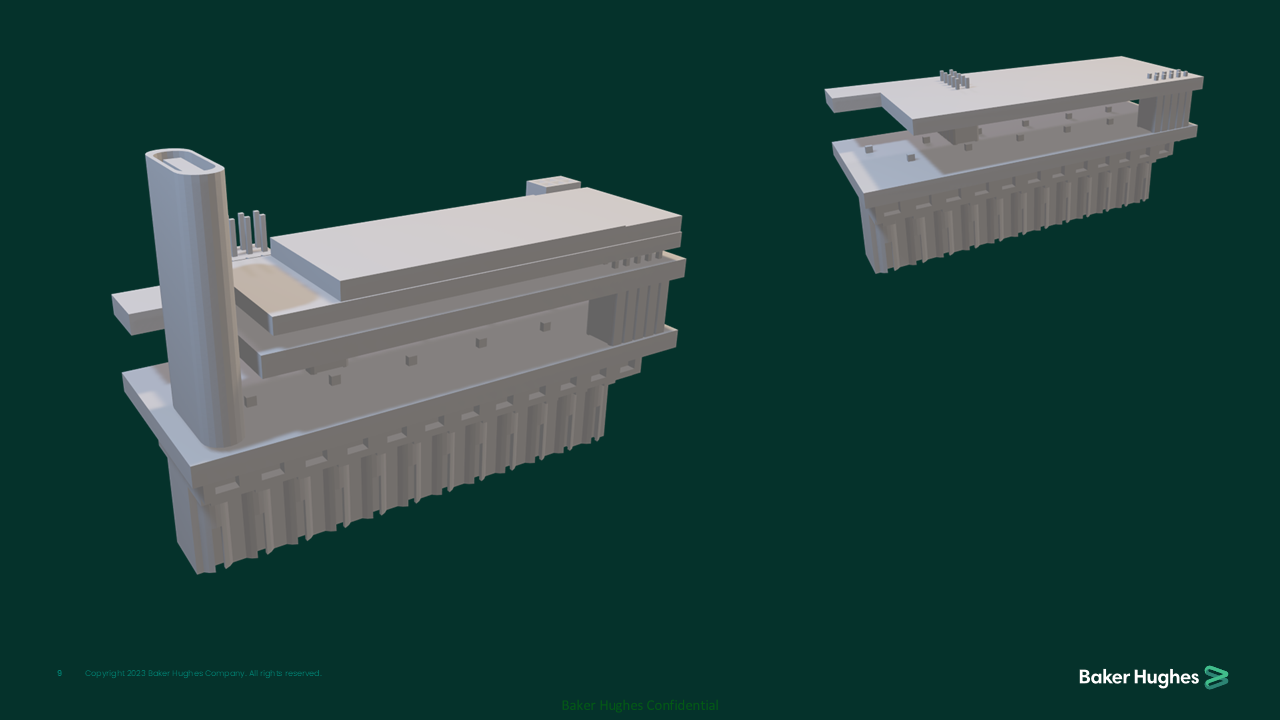

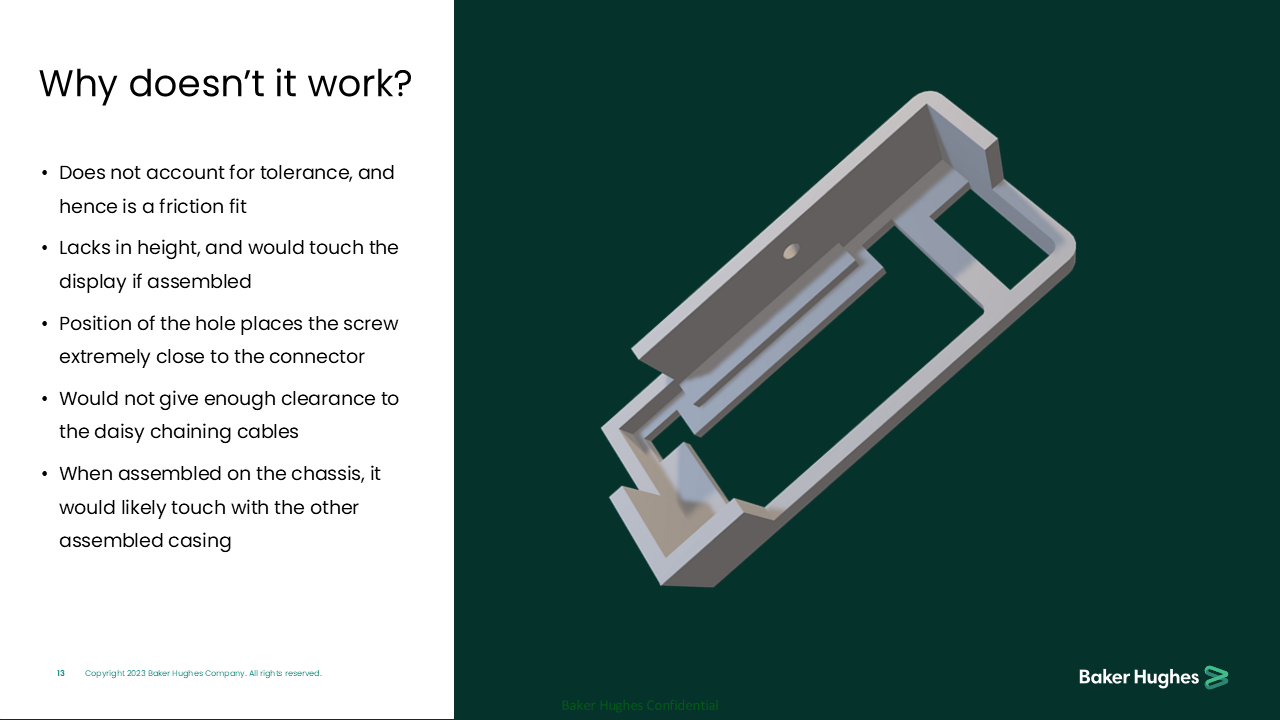

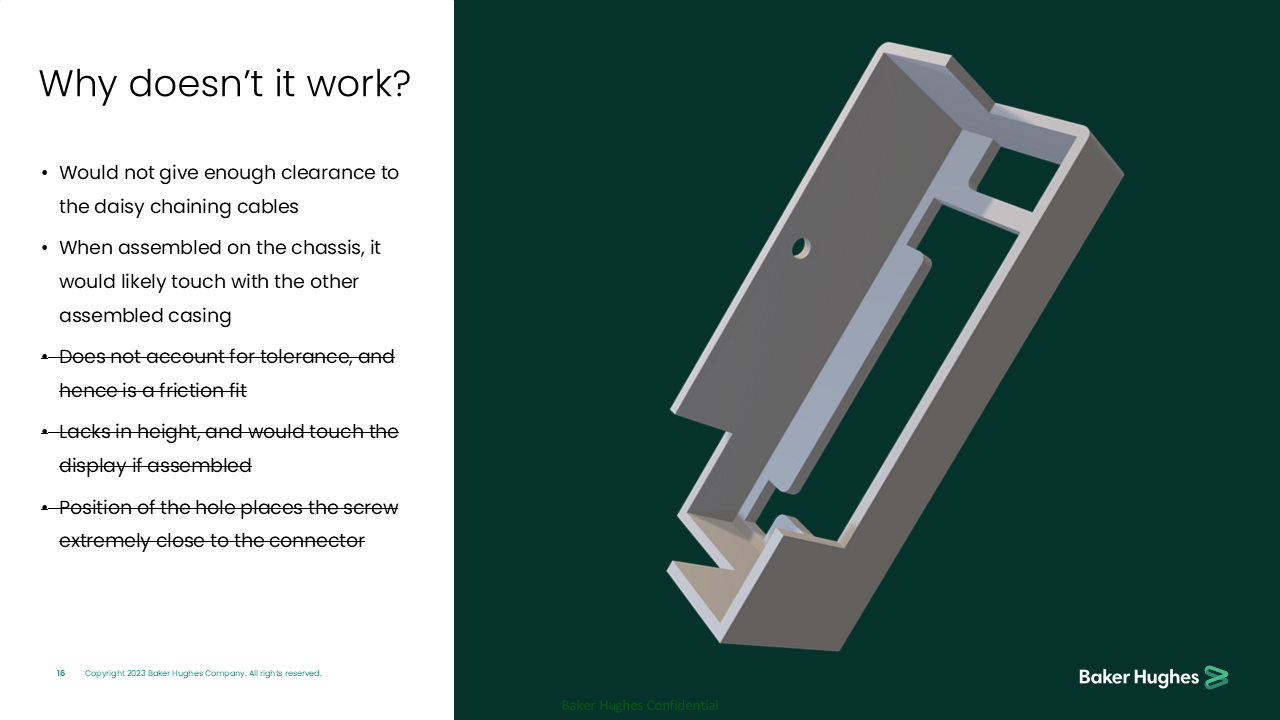

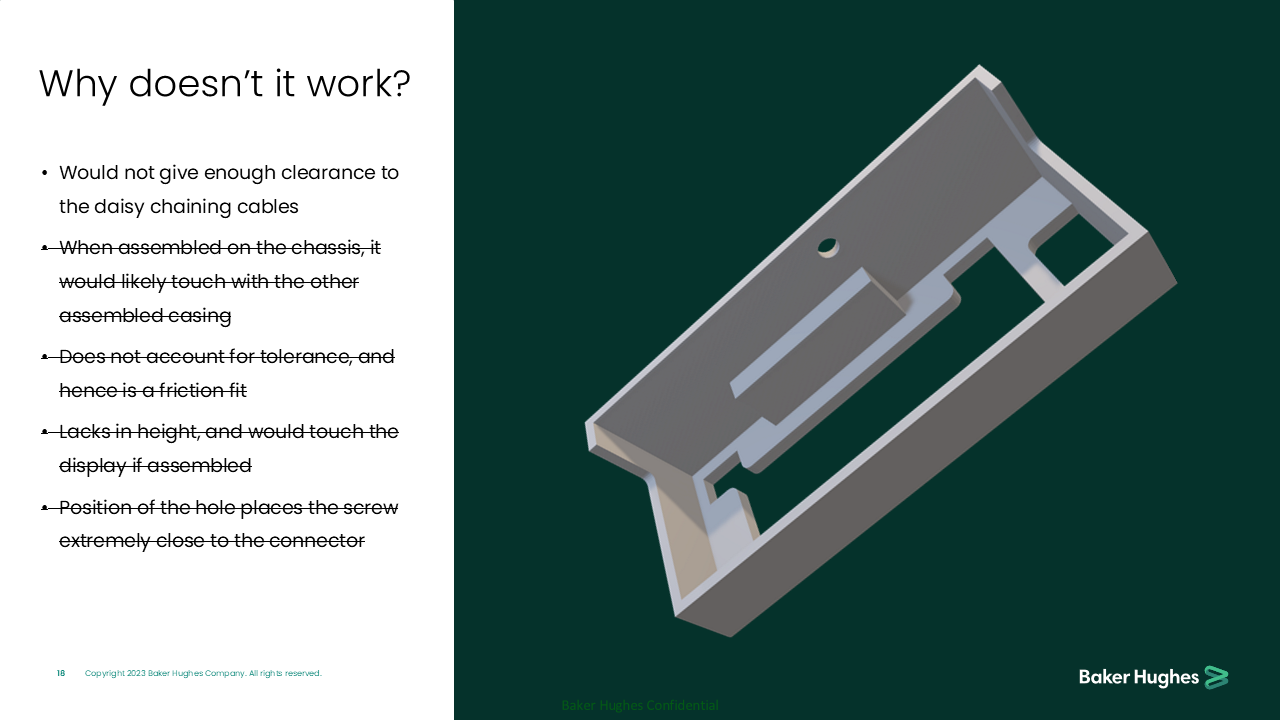

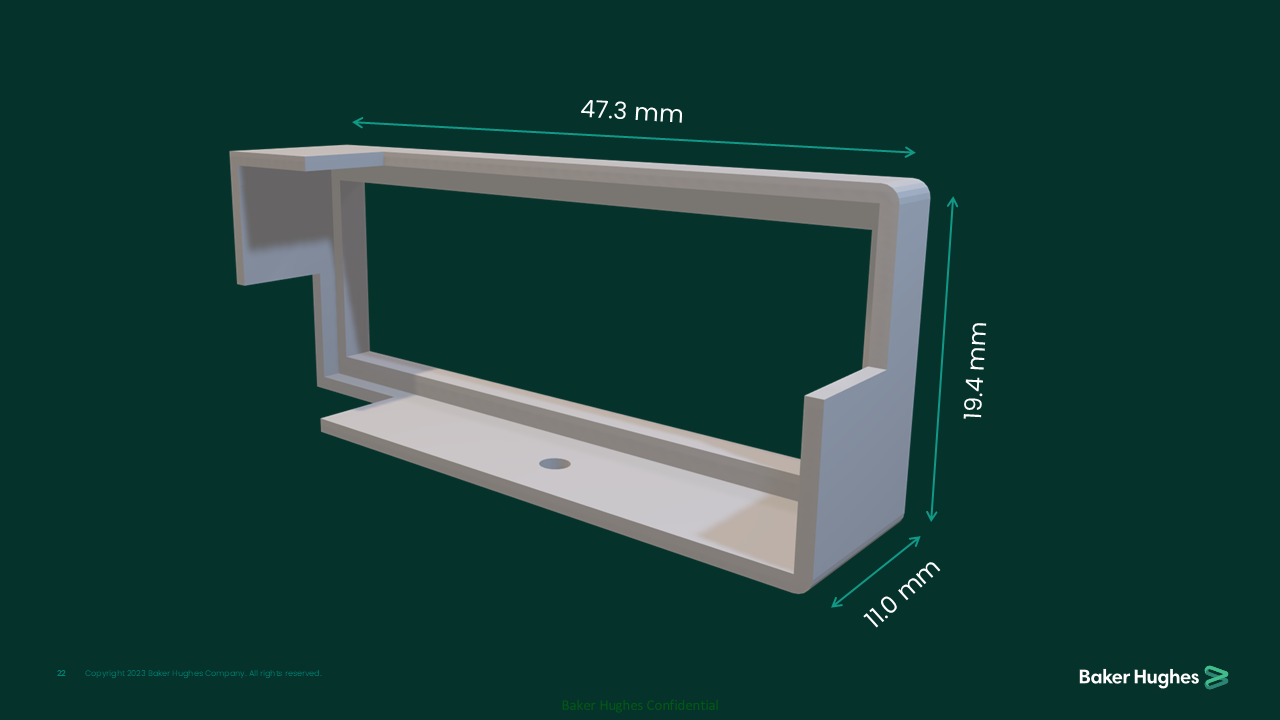

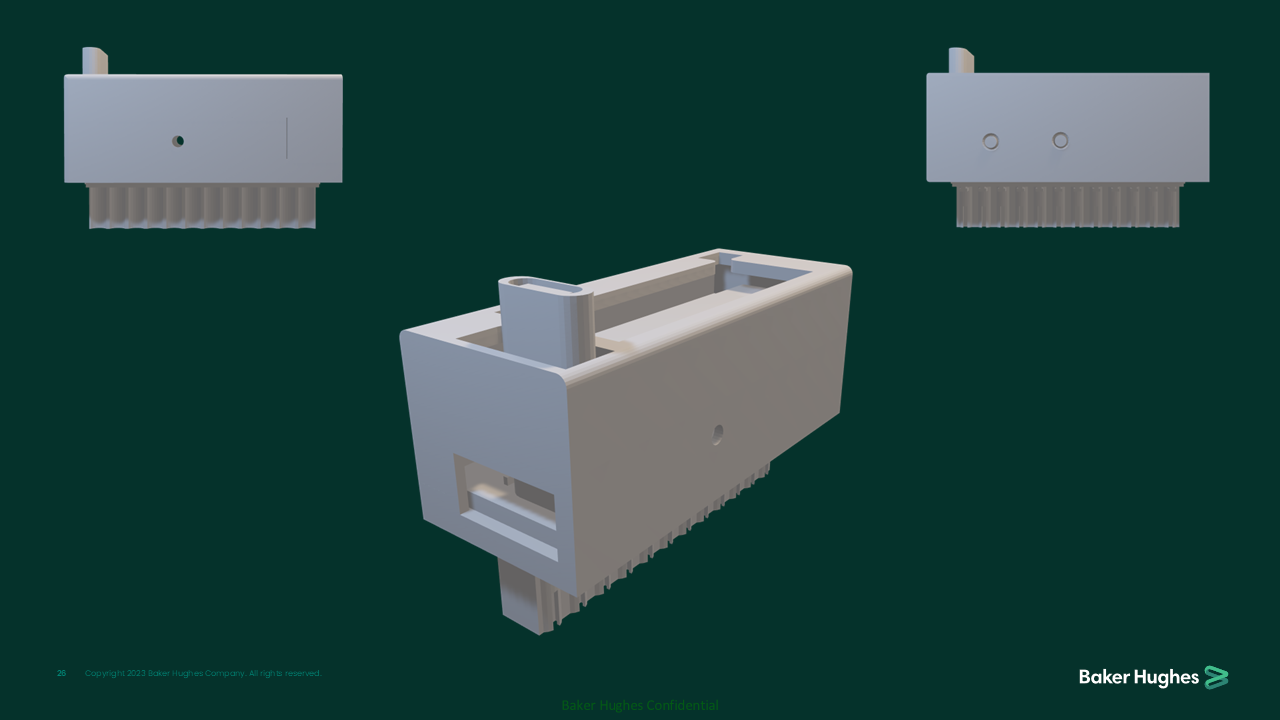

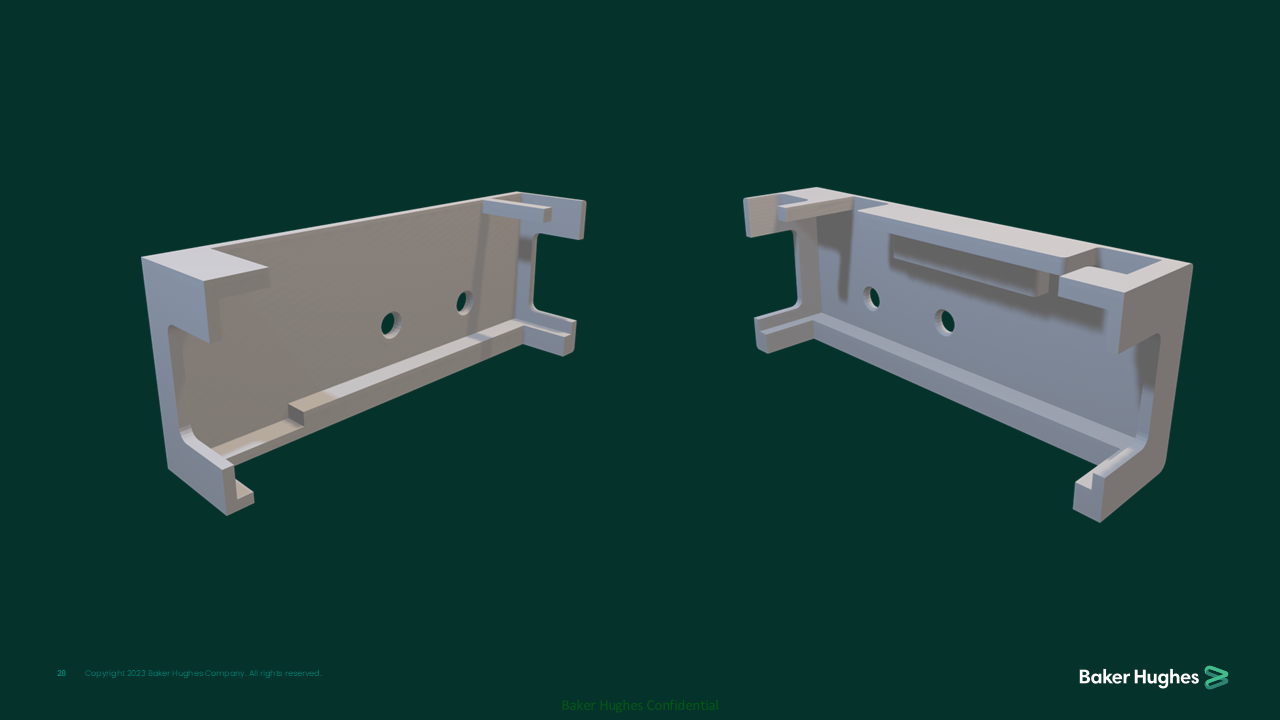

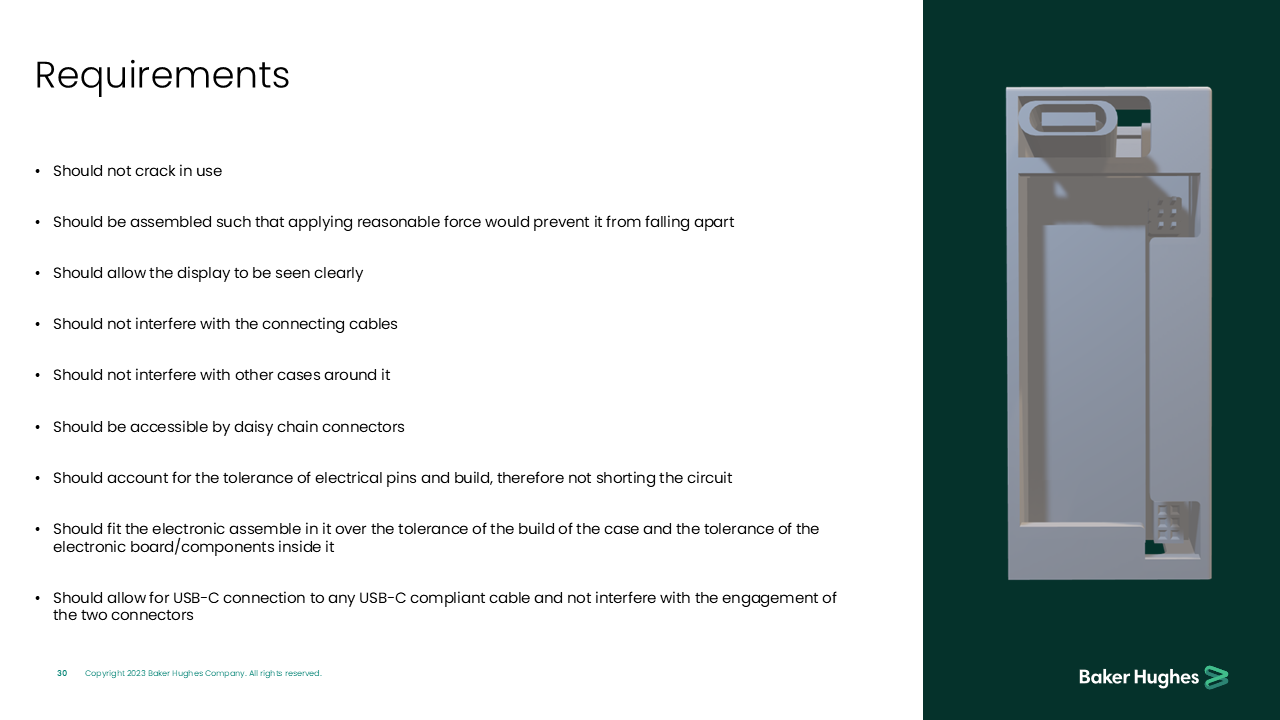

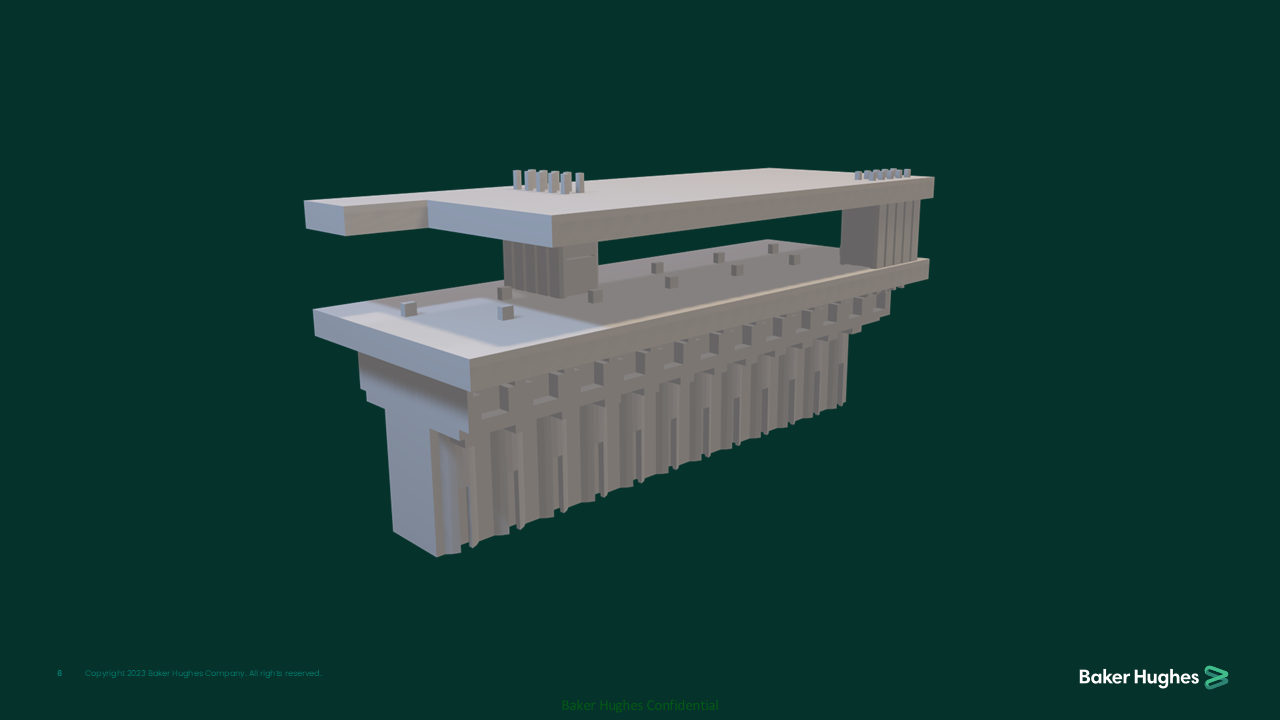

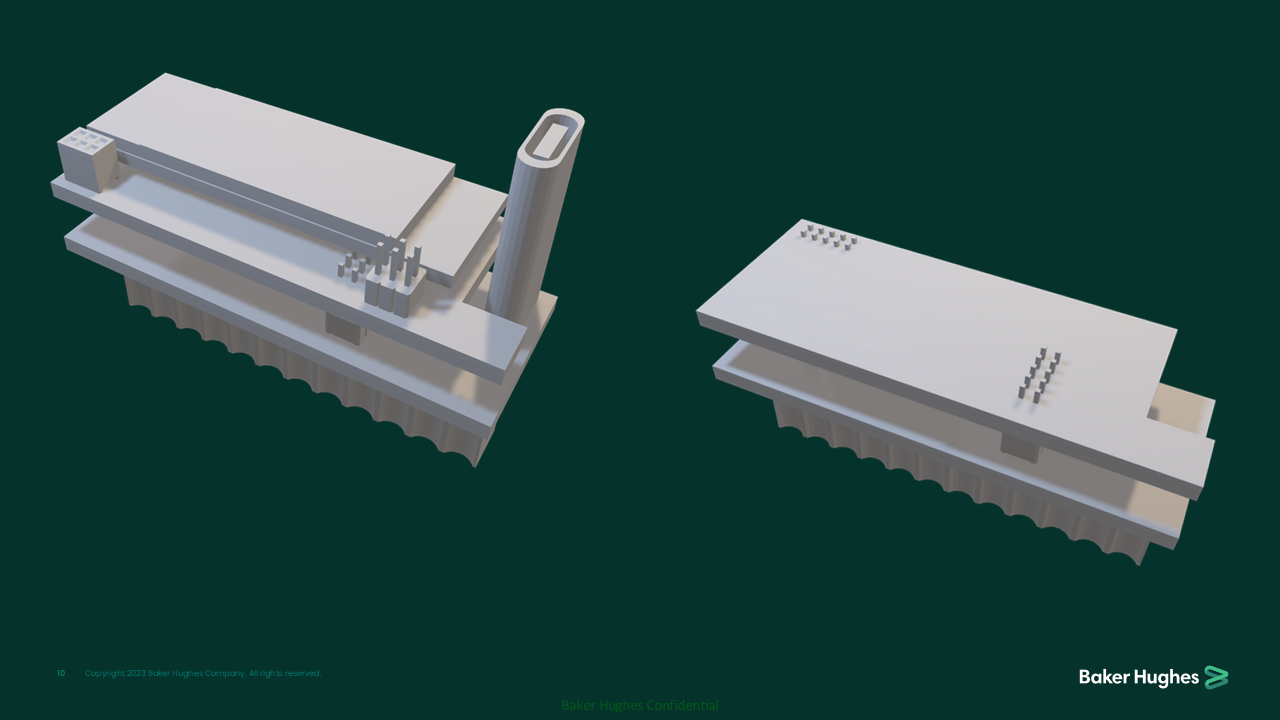

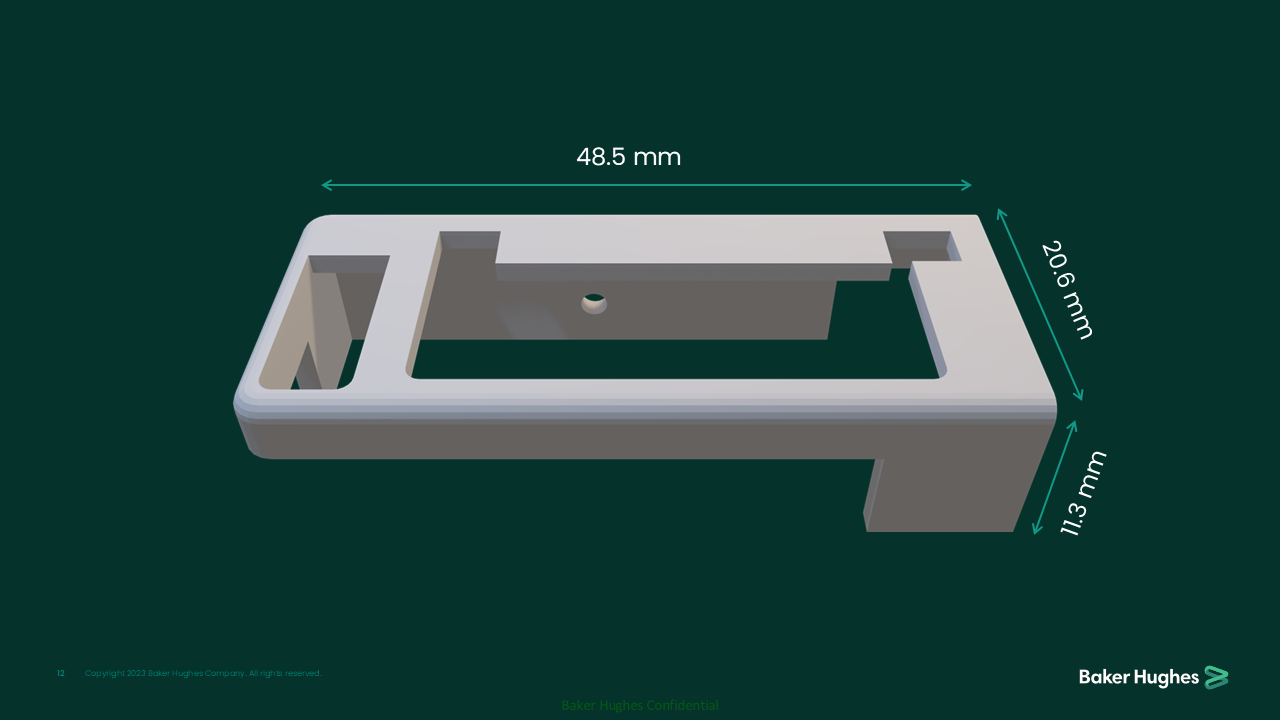

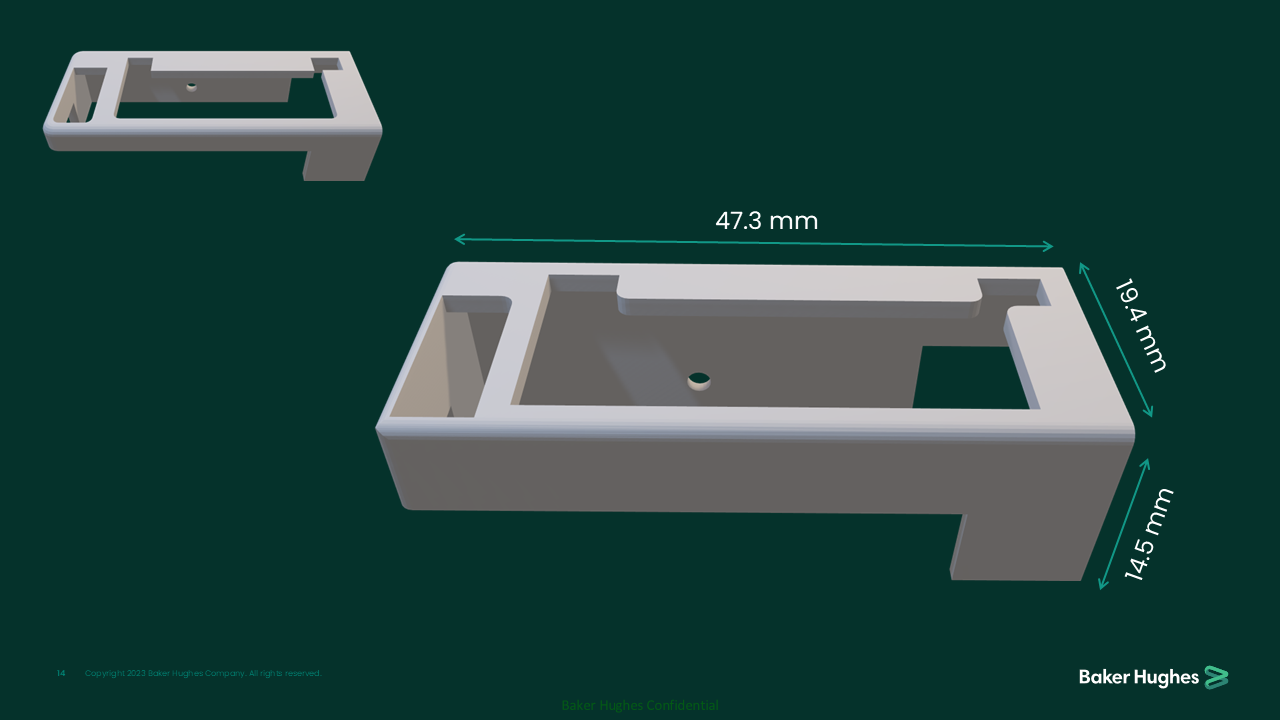

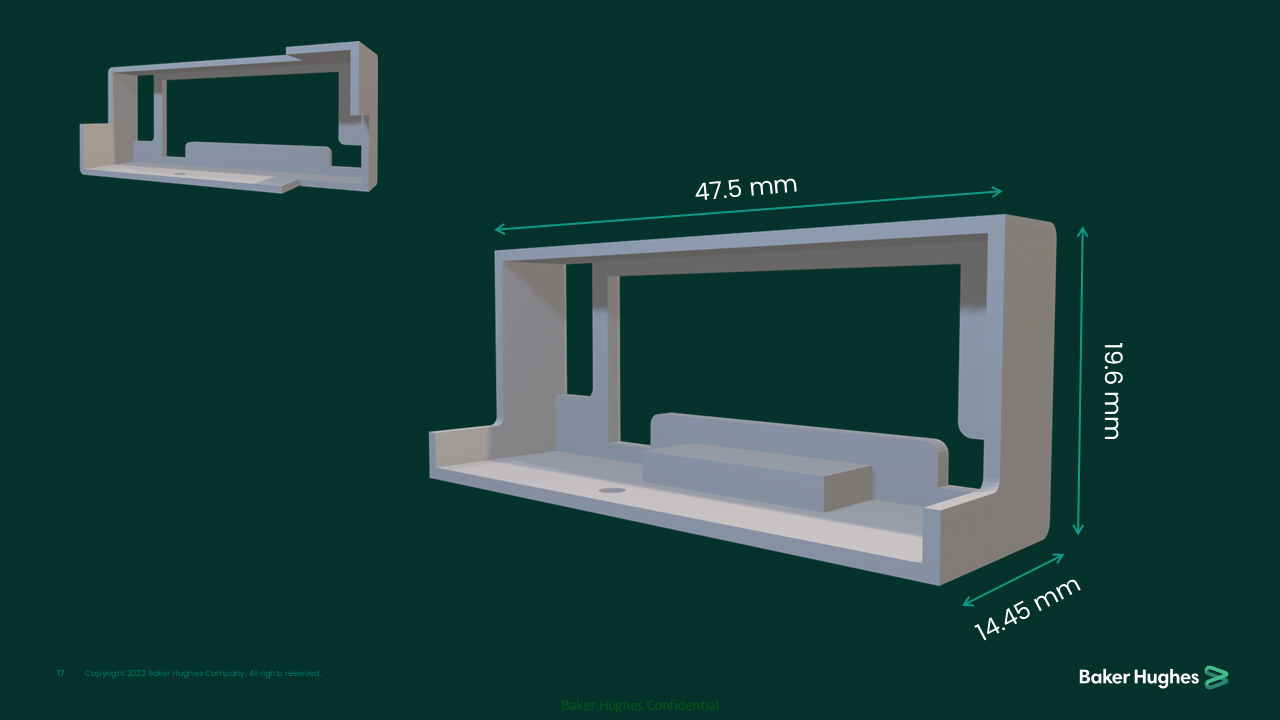

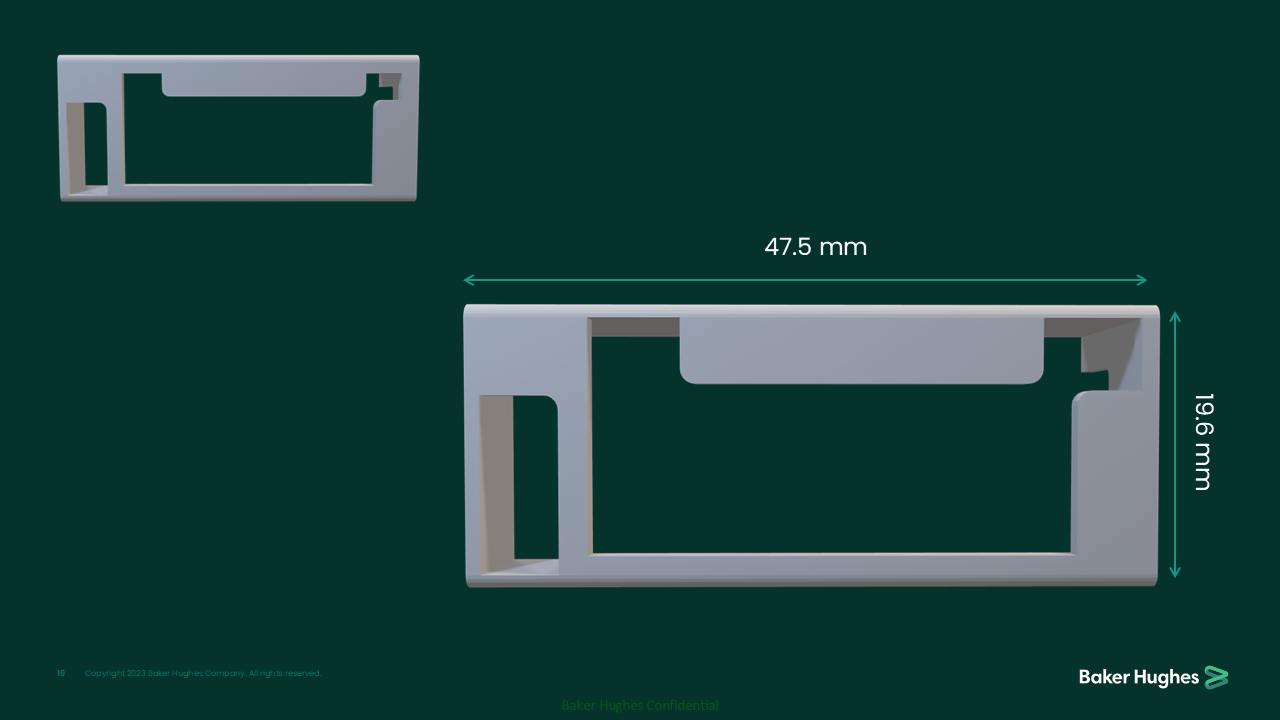

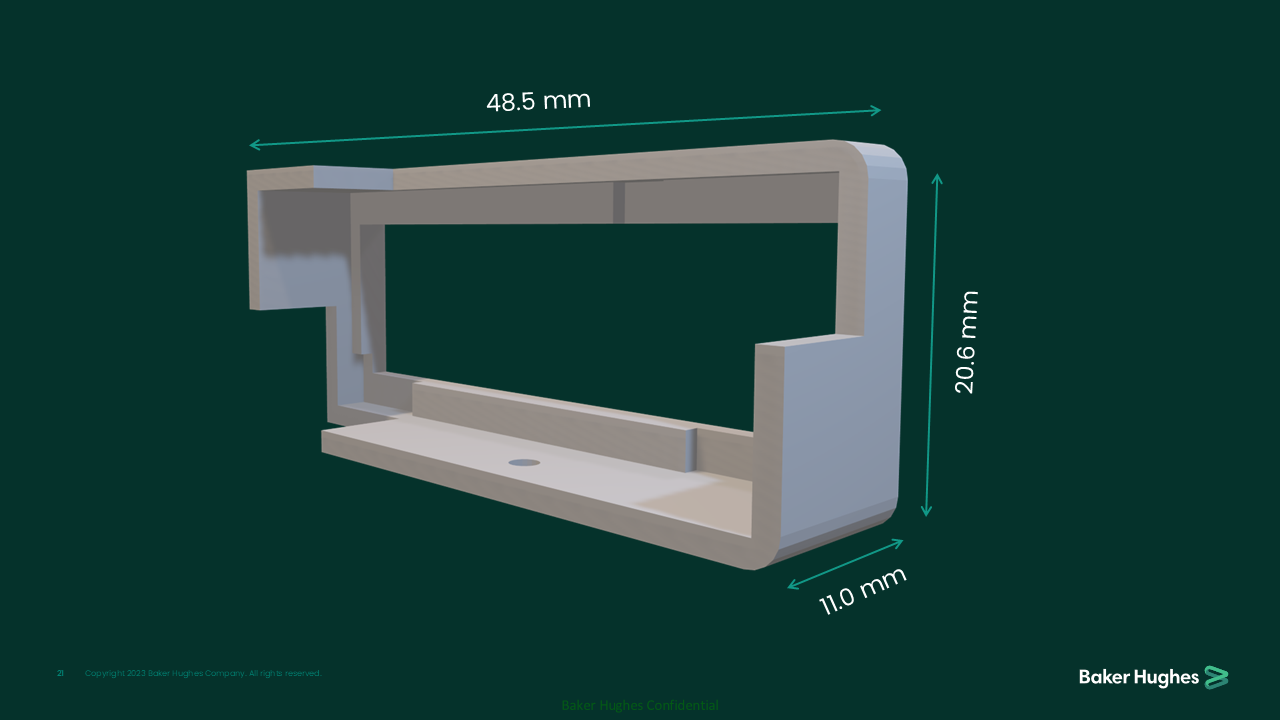

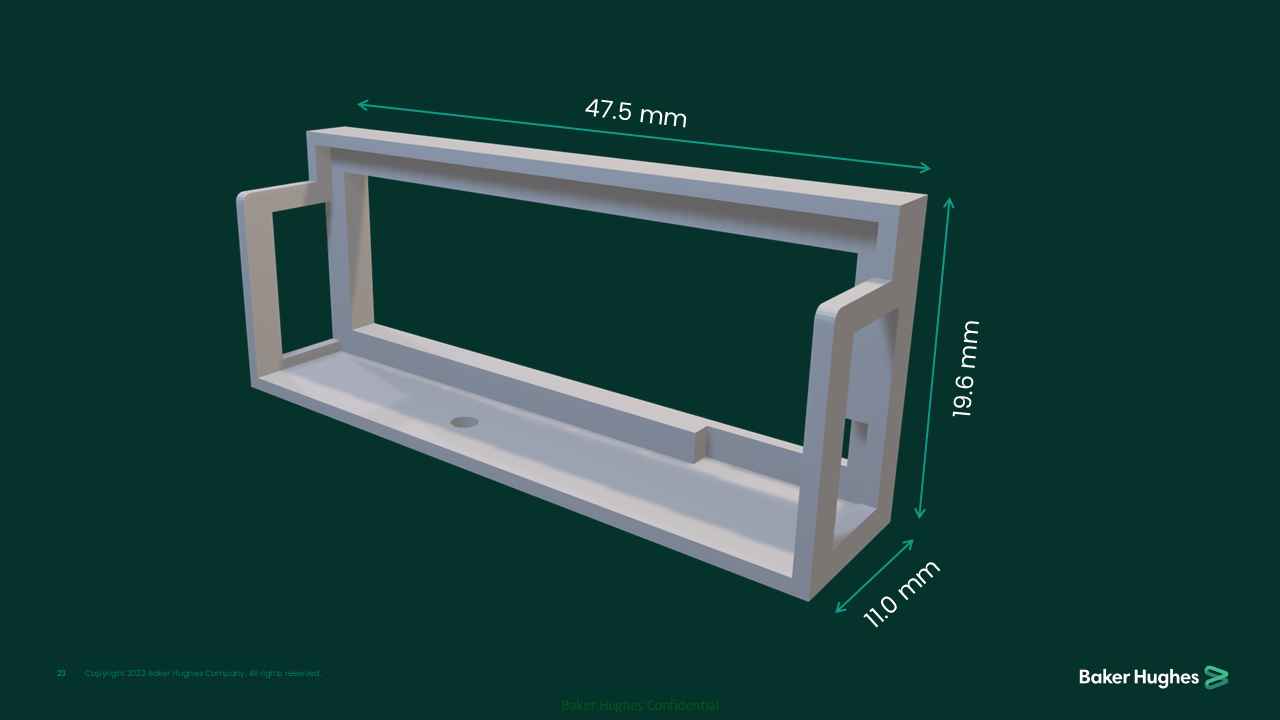

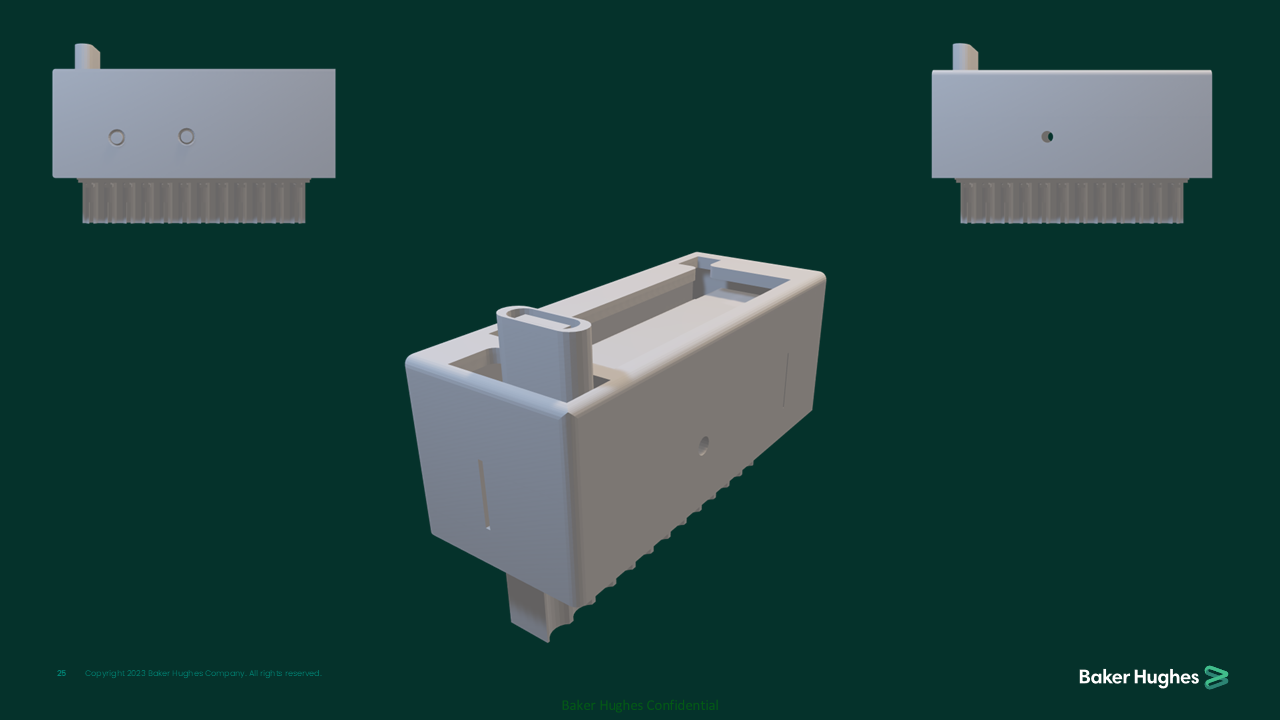

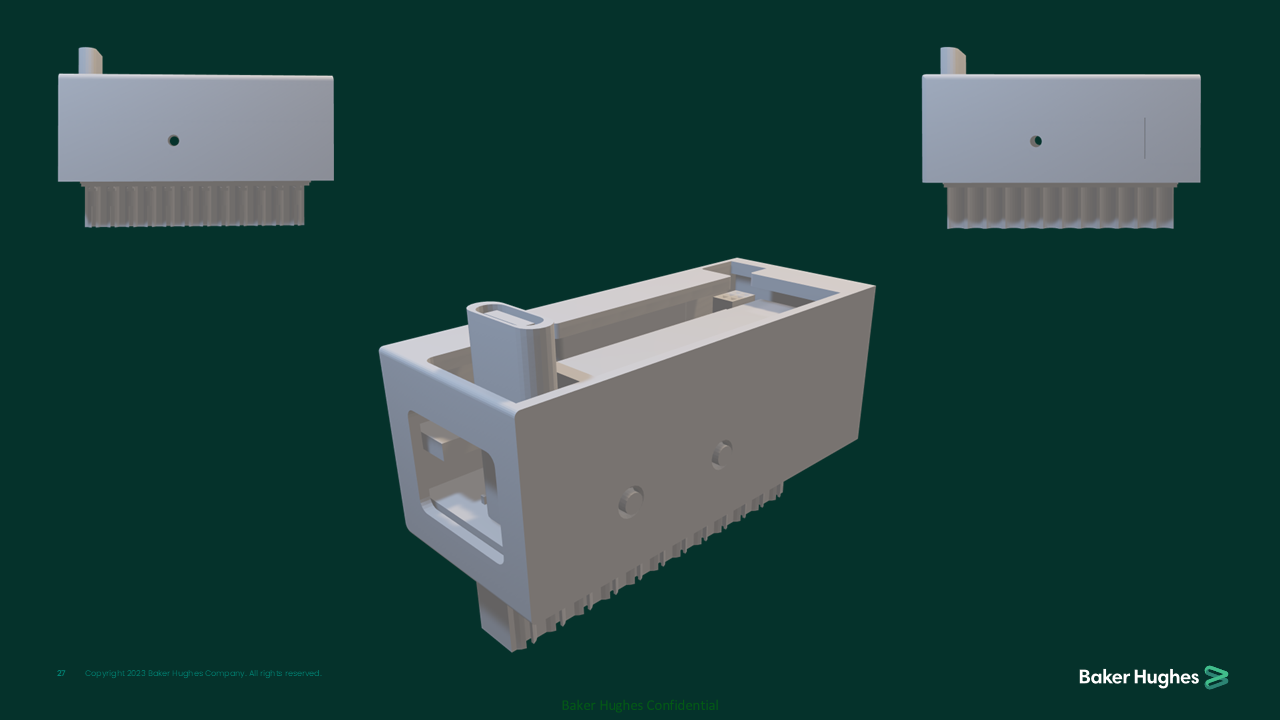

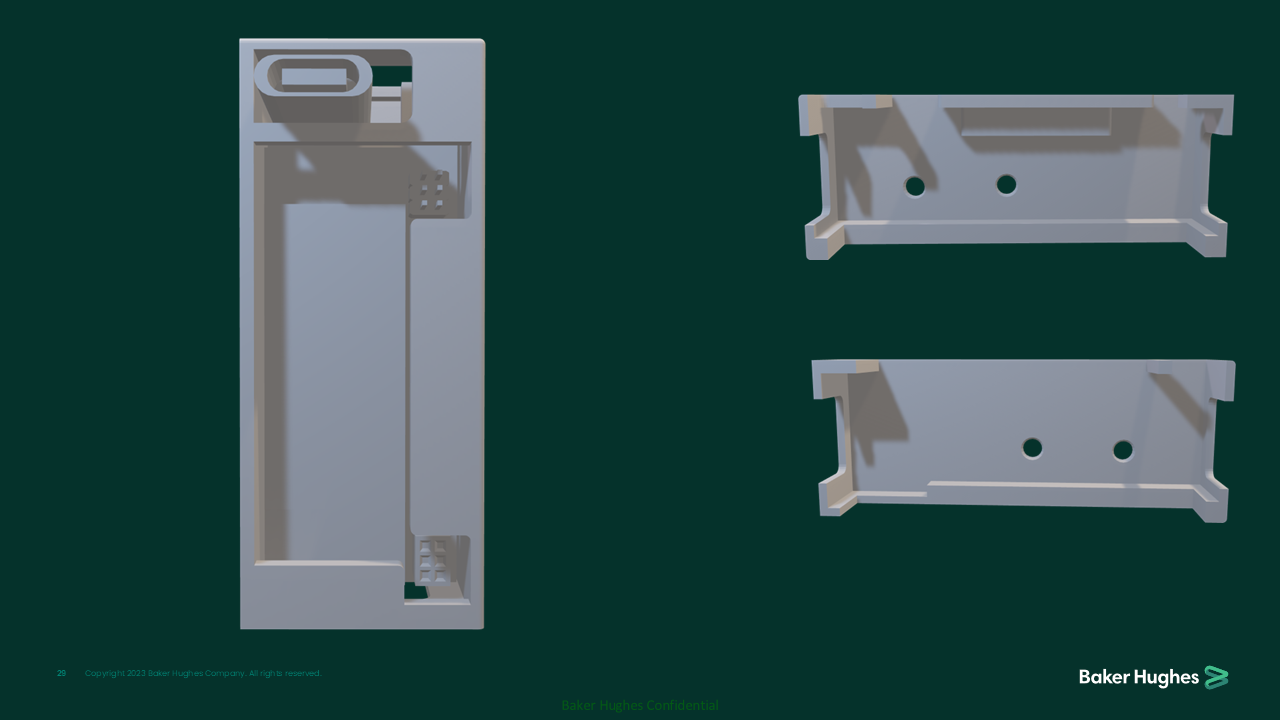

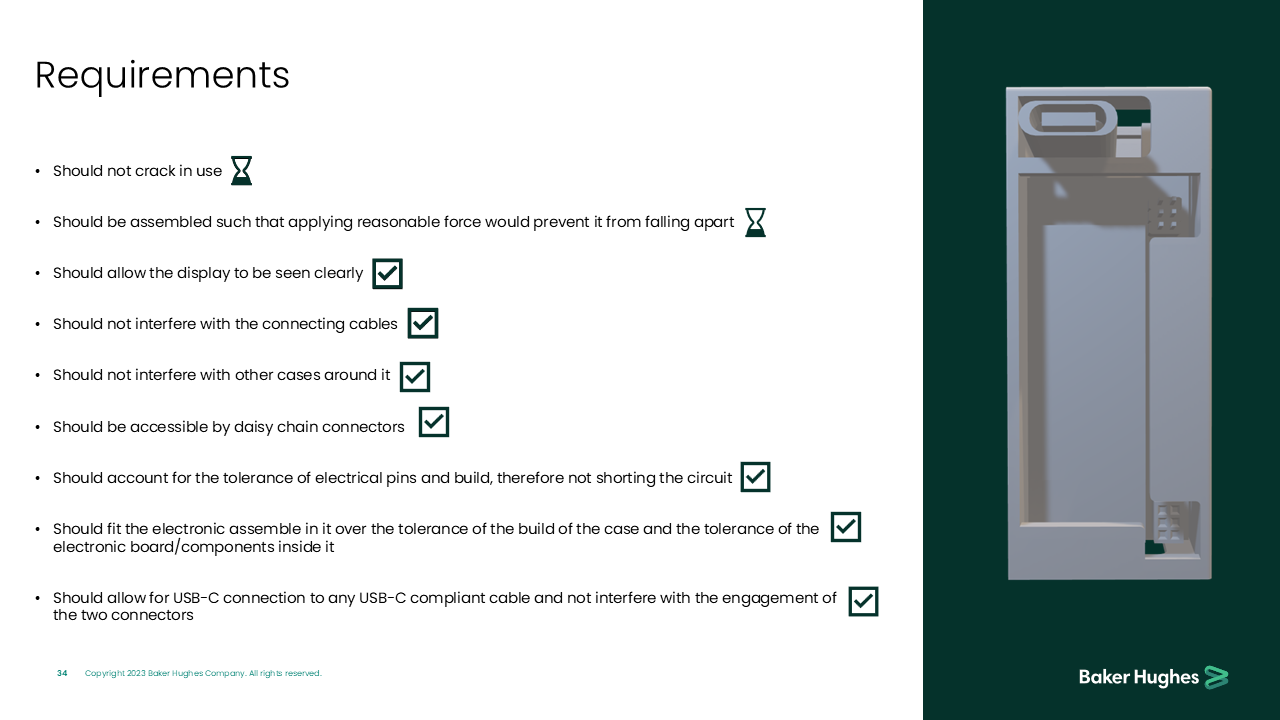

The Leviathan Casing project involved designing an enclosure that securely houses electronic components while ensuring structural integrity, cable clearance, and heat dissipation. The casing needed to accommodate tolerance variations, daisy-chain connectivity, and USB-C compatibility without shorting circuits or obstructing displays. Multiple iterations refined the design to meet manufacturability and functional requirements.

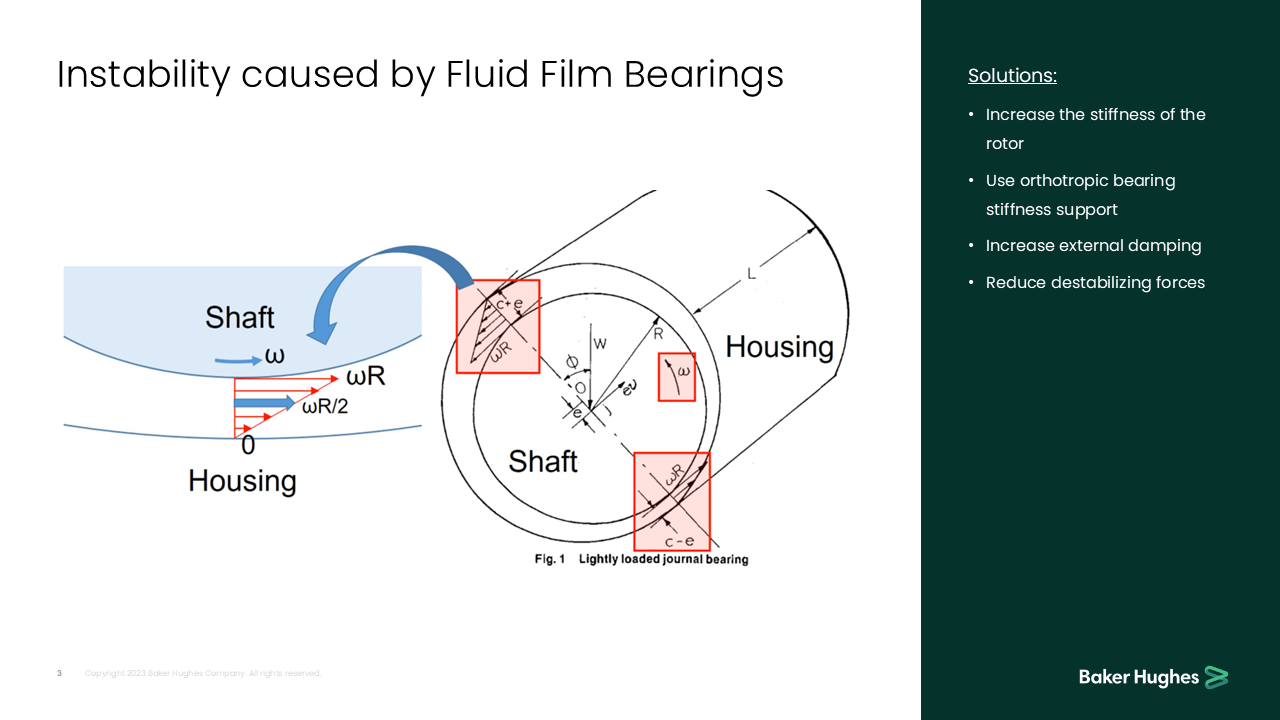

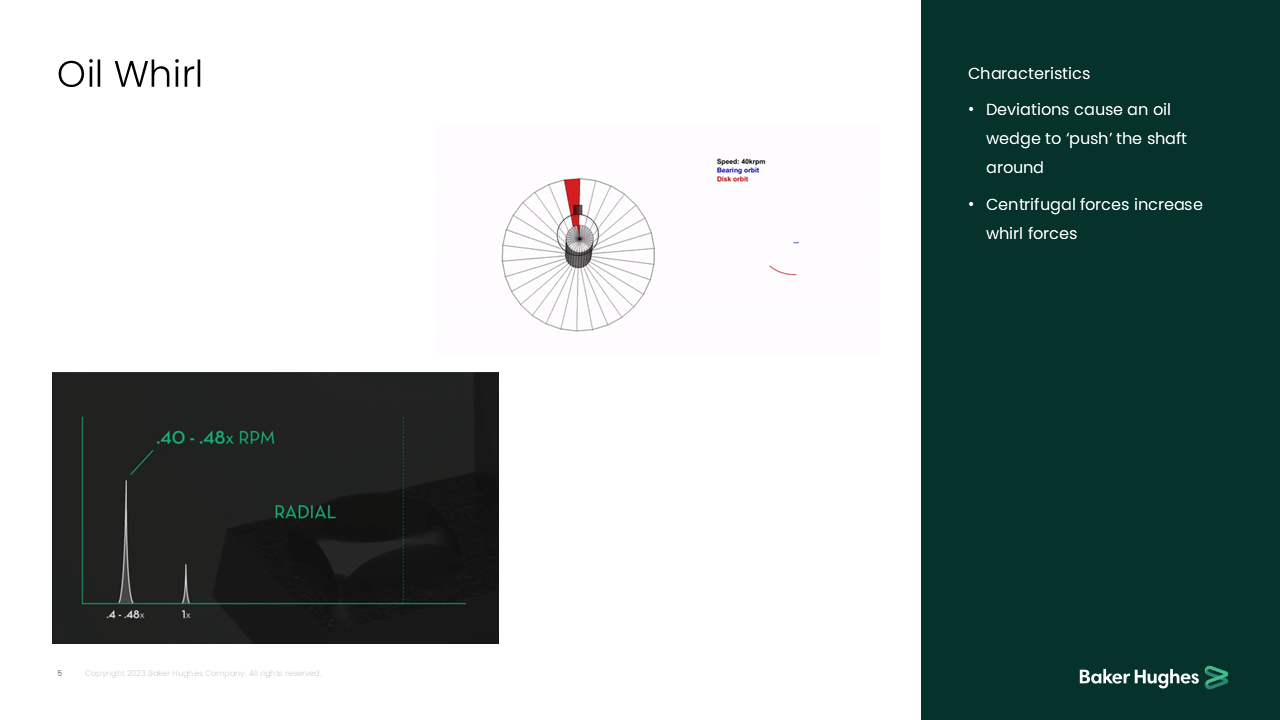

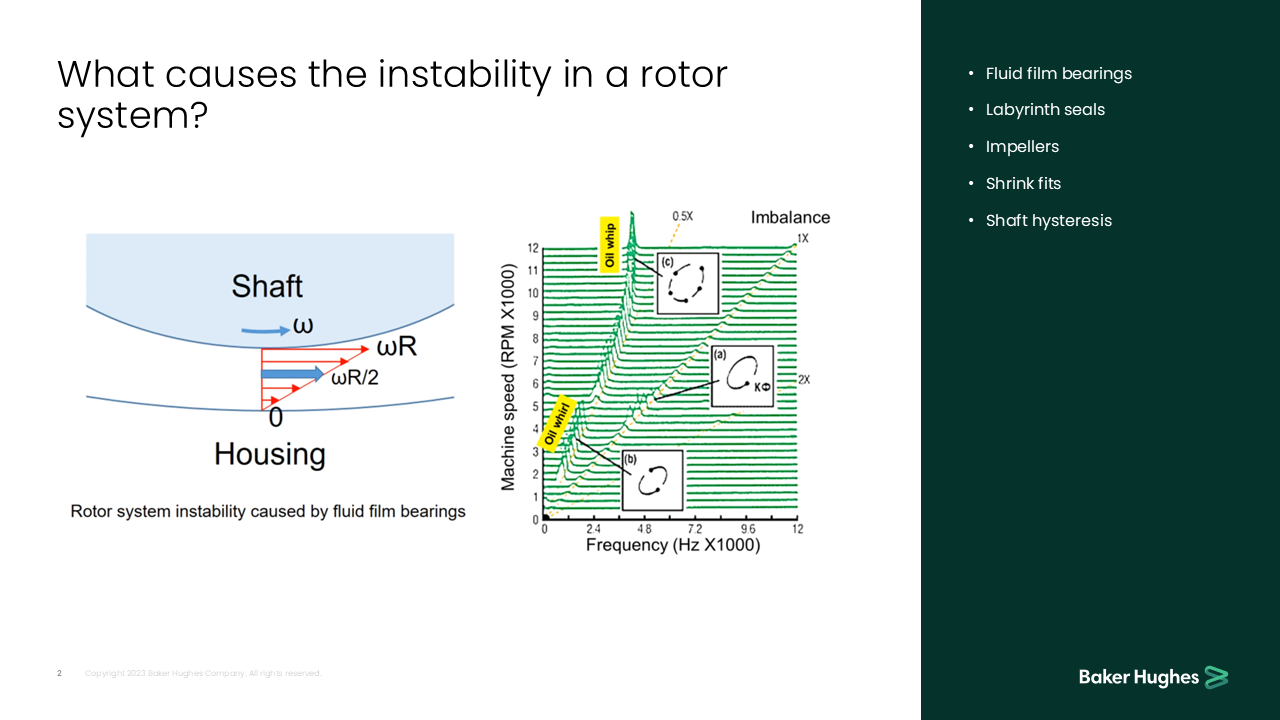

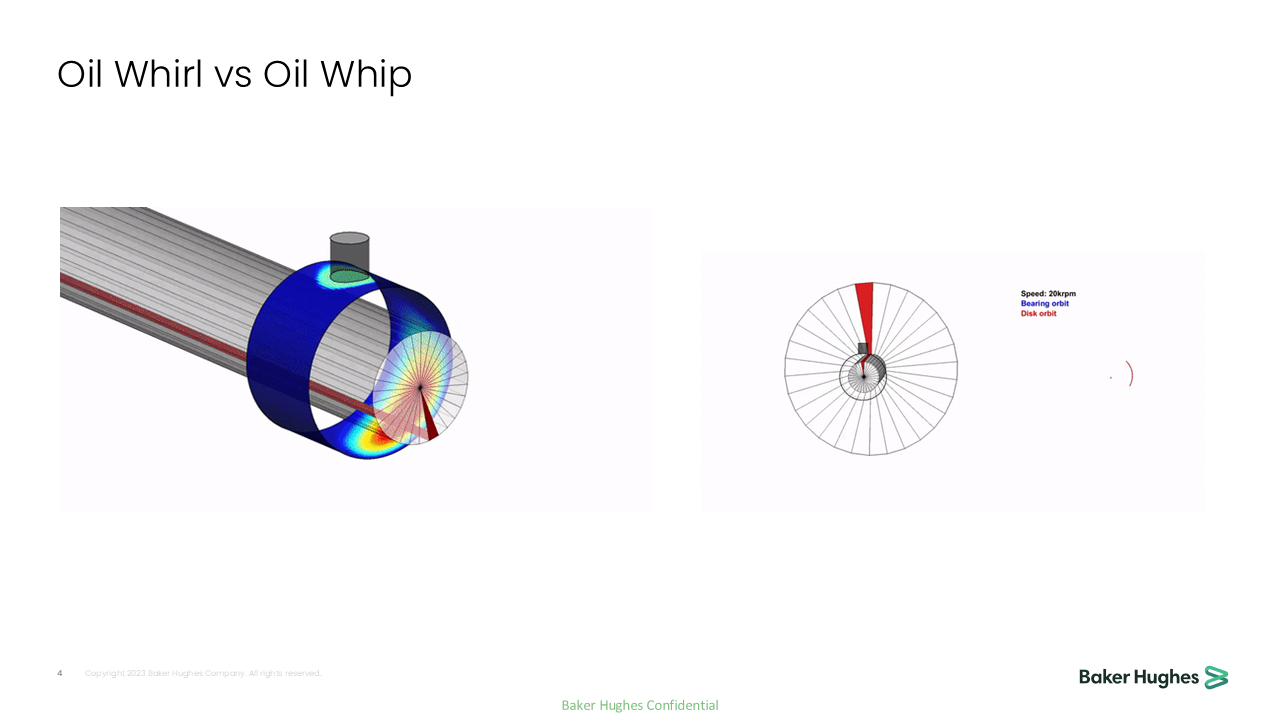

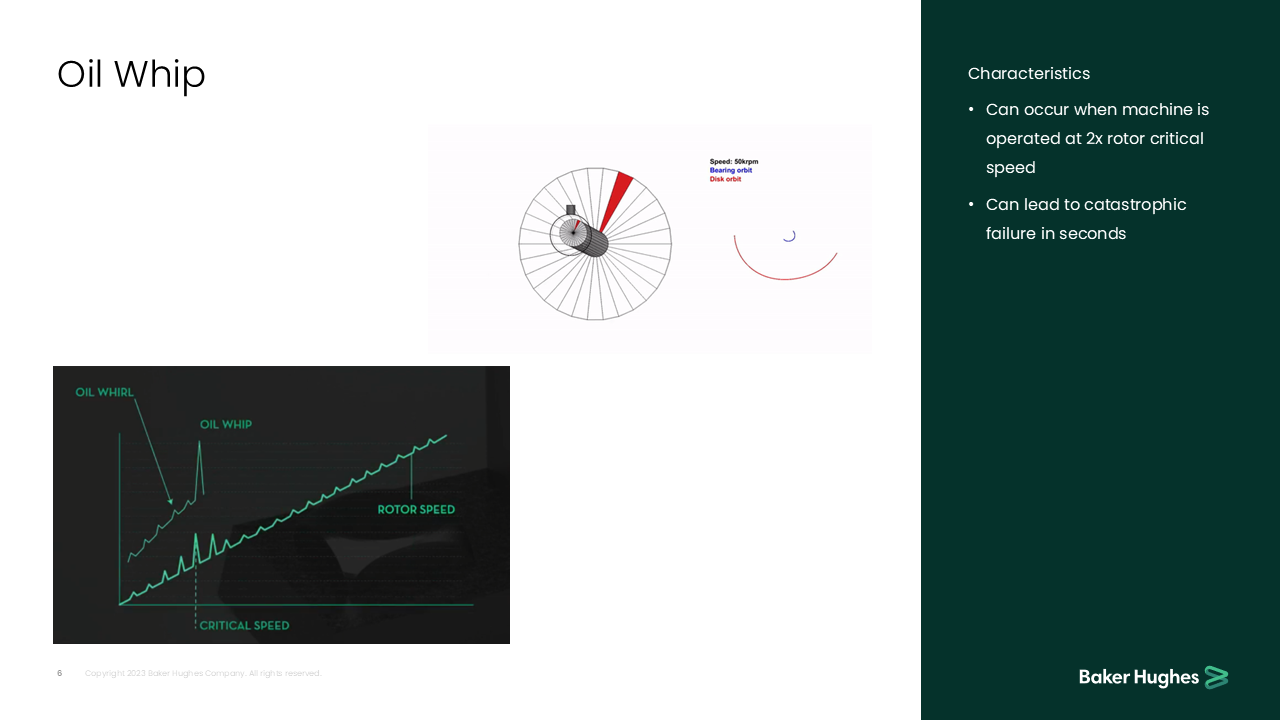

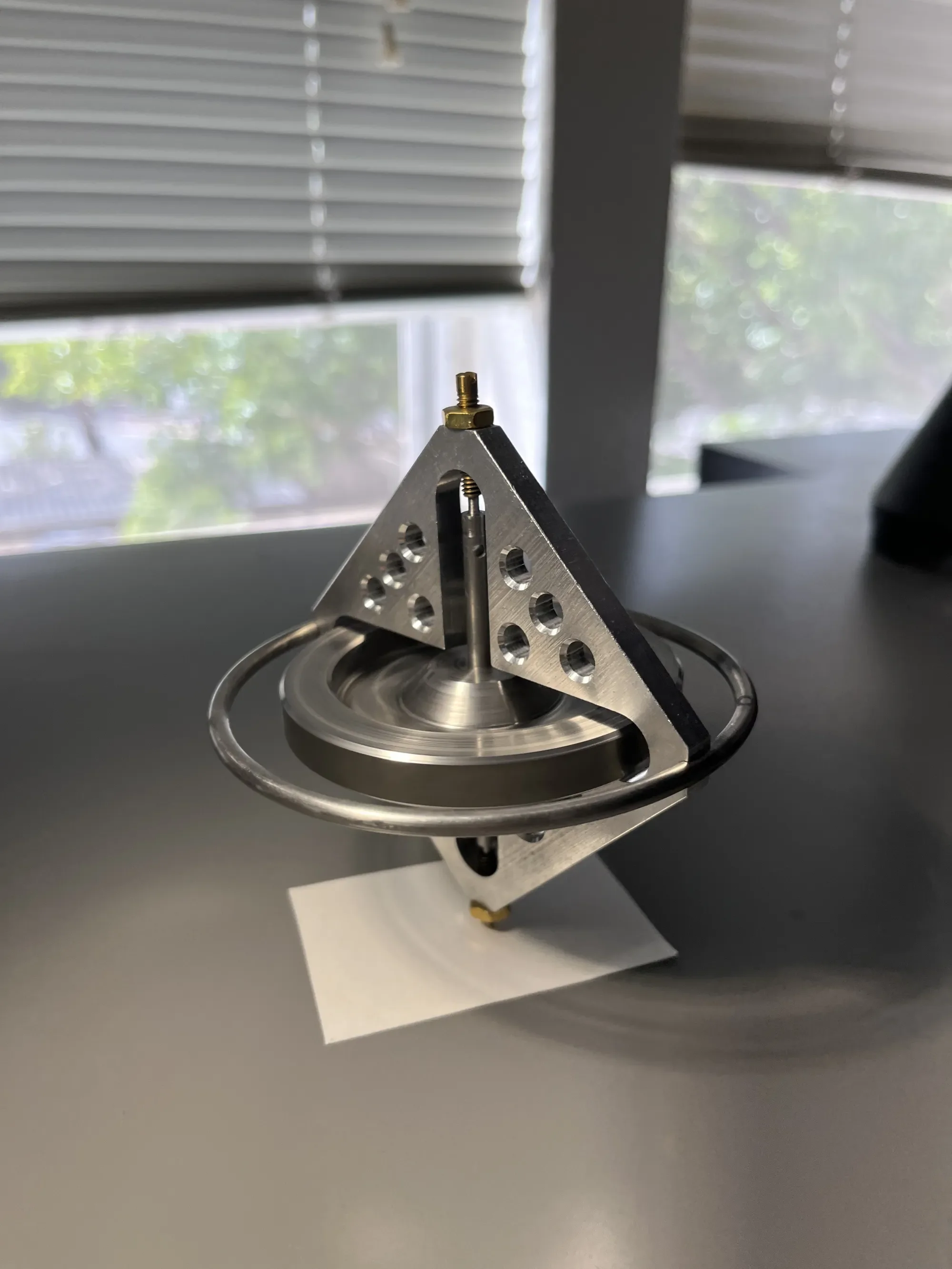

The Rotor Kit project focused on fluid-induced instabilities in rotating machinery, particularly oil whirl and oil whip phenomena in fluid film bearings. By analyzing rotor stiffness, damping strategies, and destabilizing forces, I explored ways to mitigate these effects and improve bearing design for long-term reliability. This work contributes to preventing catastrophic failures in high-speed rotating systems.